How did you promote thigh meat?

“Working with the supermarkets, we started to make thigh meat popular. Chefs also began to use thighs more frequently in restaurants. This turns out very well, because there are many dishes such as chicken sate where thigh meat actually fits the bill better than breast meat. Three years ago nobody was interested in thigh meat, but now, apart from supermarkets, industrial customers such as fast-food restaurants and caterers are coming to us because they also want to work with thigh meat.”

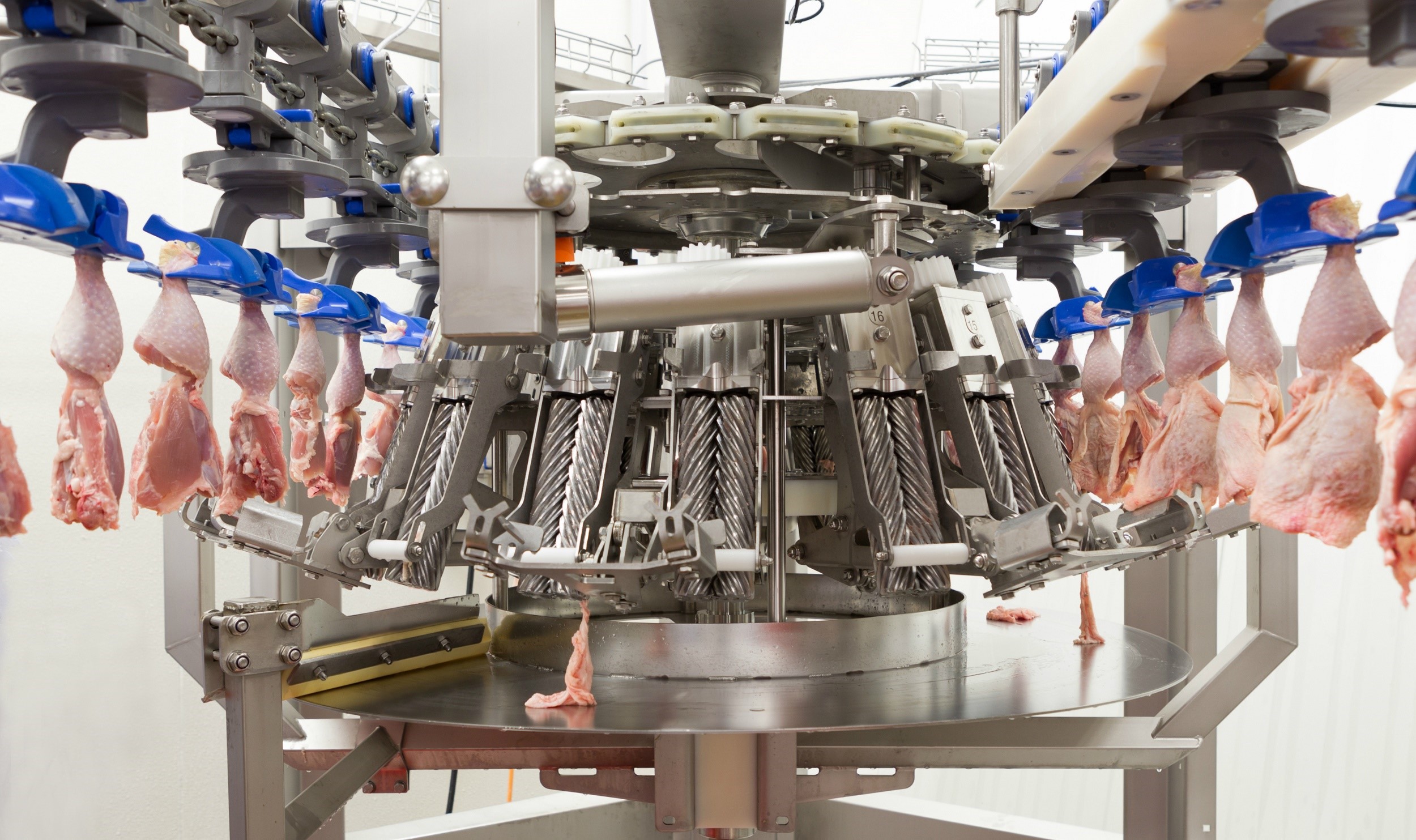

How do you process chicken legs?

“It is only three years since we were manually deboning some 4, 5 tons a week on a simple trimming table. This business continued to grow to around 70 tons and we had a huge amount of people at work. Then I saw the Marel Thigh Fillet System at the Poultry ShowHow in 2017. That was an ideal option for us, because we didn’t want to have to debone whole legs. That’s a totally different market, which we don’t want to be in. Retailers aren’t interested in whole legs, only in thigh meat. The same goes for our industrial customers, who want to supply their outlets throughout Europe with thigh meat.”

What is your input product?

“We get saddles [back halves] from our processing plant. Five people shackle them manually at a speed of 7,200 per hour [120 pm]. We have chosen saddles instead of separated legs because of the high efficiency of the JLR anatomical leg cutter. The JLR succeeds in really keeping the oyster on the leg. That extra bit of yield when compared to a "normal" leg has a significant impact, when we’re talking about such large volumes".