Steven Wang mentioned that automation, intelligence and digitization have become the clearest trends in the food industry, especially in the poultry processing industry. In China, labor resources are decreasing, while fewer and fewer young people are willing to work in slaughterhouses. As a consequence, the labor cost is rising quickly.

Marel outlines the poultry processing trends in China

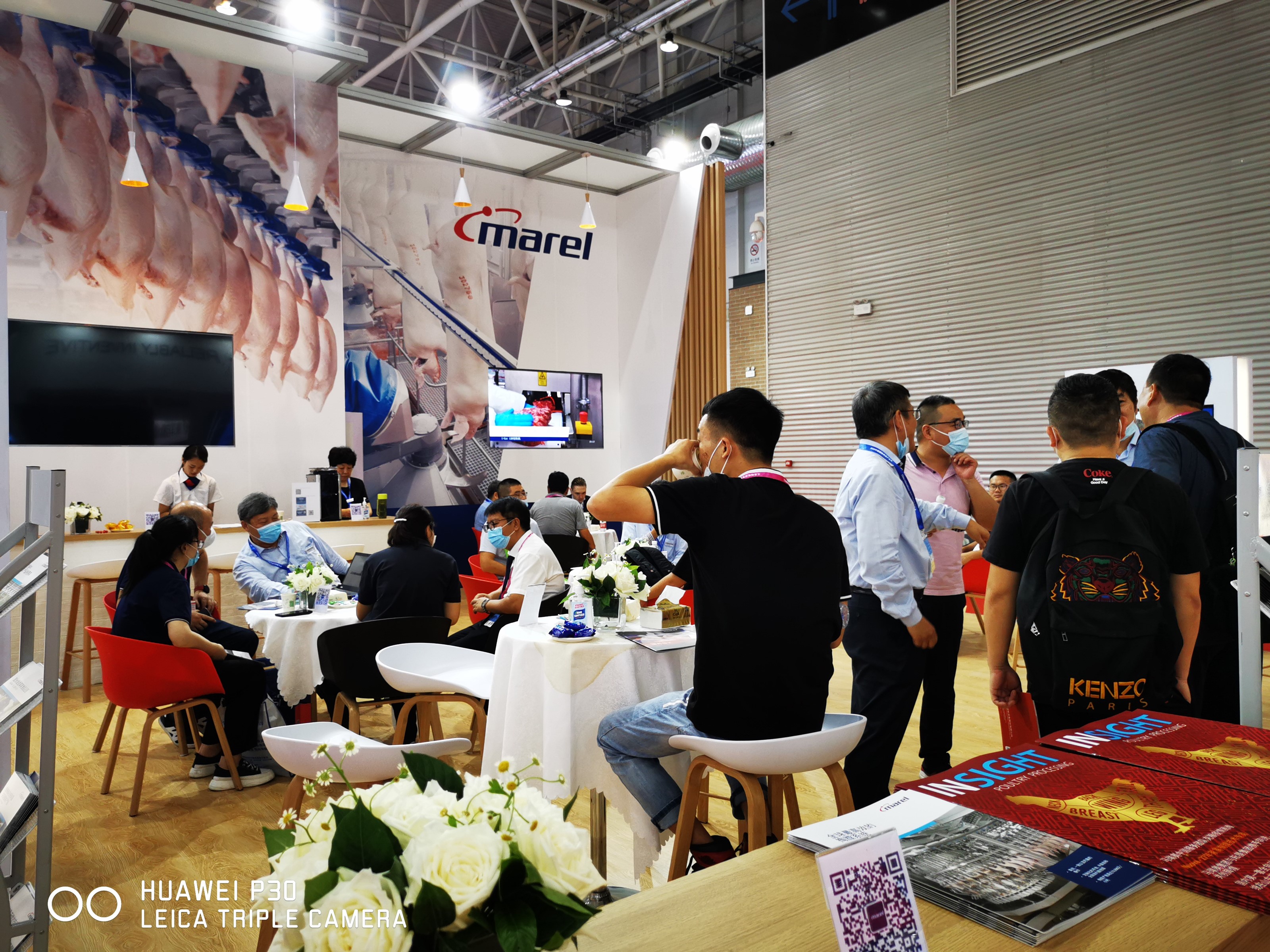

Meat/Poultry Forum 2021 in Huangshan City

On June 29, 2021, Marel China participated in the 12th China Meat/Poultry Processing Technology Development Forum held in Huangshan City, China. Steven Wang, Sales Director of Marel China Poultry, gave a speech titled "The latest progress in automated poultry processing technology." The audience showed great interest in the subjects he touched in his speech.

Industry intelligence

The Covid-19 outbreak brought along many uncertainties. This made the industry rapidly move to a larger scale of automation. At the same time, food processing enterprises are constantly pursuing optimal production efficiency and output, pushed by a rapidly developing so-called central kitchen* and new retail business. Striving for such an optimization obviously increases the complexity of the production in a processing plant. These factors all promote the development of an "industry intelligence".

The consumers' demand for traceability of their food products is becoming more and more intense. This requires an elevated level of digitization. It is, therefore, no wonder that digital technology based on the Internet of Things and Artificial Intelligence is developing fast in the poultry industry.

More than 200 processing lines

At present, China's poultry industry faces many challenges, such as the annual processing of 5 billion white broilers in China. This requires more than 200 automated processing lines, which is a great challenge but, of course, offers excellent opportunities to equipment suppliers.

China consumes 10 billion yellow chickens and ducks every year. At present, the processing of these birds, especially the evisceration, cut-up and deboning operations, still rely heavily on manual processing. However, the labor cost of China is rising year by year. How to turn this part of processing into automated operations is a big challenge for Chinese poultry enterprises. Most of the poultry processing companies are still in a very early stage of data collection and analysis.

In line with the automation, intelligence en digitization trends and challenges faced by the poultry industry, Steven Wang introduced Marel's solutions. They included the Nuova evisceration, AMF-i, Thigh Fillet System, IRIS, further processing solutions as well as Innova, the digital software platform.

* 'Central kitchen' is a new concept in China. Instead of cooking all food in their own kitchens, foodservice companies, such as restaurants, buy their cooked or half-cooked dishes from a so-called central kitchen. This could be a supplier or a large-scale kitchen owned by the restaurant chain. The advantage of a central kitchen is the standardization of dishes, cost reduction and shortened cooking-time at the restaurant. It is similar to pre-baked bread in the baking industry.

News

Get in touch

Our dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.