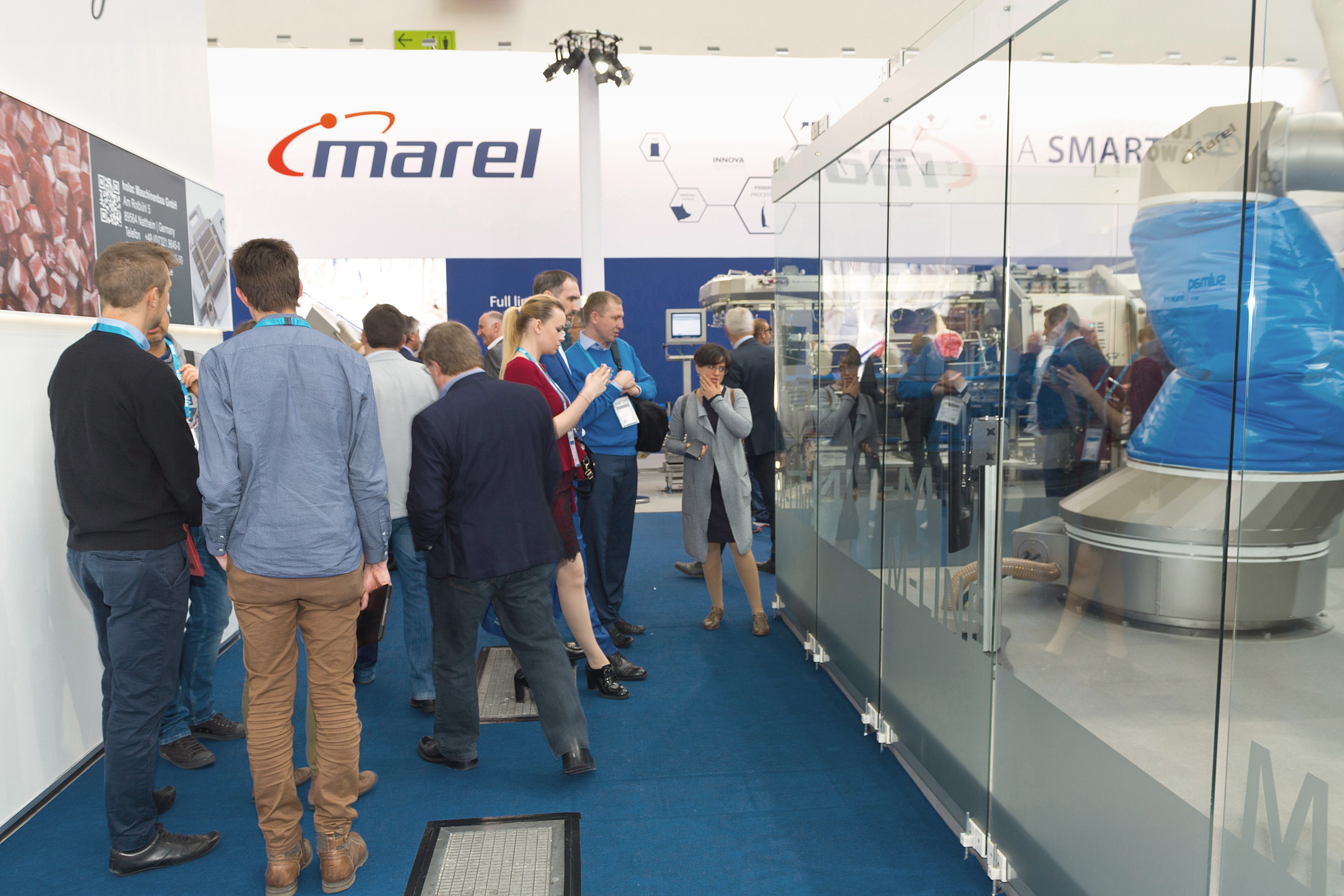

Visitors to the Marel stand were given an insight into how meat processors can find smarter ways to approach modern food production challenges. ‘For Marel that means automating and optimizing processes through the value chain – from live animal to finished product at the supermarket’, explains David Wilson, Managing Director for Marel Meat. ‘What Marel is demonstrating at IFFA 2019 are the latest, state-of-the-art advances which allow processors to do things in an optimum and intelligent way.

Twenty new solutions launched at IFFA 2019

At the IFFA international trade fair in Frankfurt, Marel introduced 20 new solutions covering the meat processing value chain, setting standards for flexibility, efficiency, food safety, traceability and product diversity.

As announced in the lead up to the event, Marel launched numerous new products and solutions at IFFA 2019. Dorthe Mohn Christensen, Marketing Manager, Marel Meat explained how exciting it has been for Marel to develop and keep building on their proven solutions. ‘Meat processors need to be smarter than ever to meet customer needs and remain competitive. Marel helps processors do this by supplying them with the hardware, software and service they need to evolve and consistently make the best use of processing technology.

Highlights at IFFA 2019

New robots for the M-line automated slaughter

The new M-line robots made their first appearance at IFFA 2019. They will further extend the existing series of efficient, labor saving and hygienic slaughter robot developments. Leaf lard removal is recognized as one of the toughest jobs in the slaughter process but the new M-Line robot solution does the job precisely, efficiently, and without damage to carcass surface or remaining organs.

New extension to the DeboFlex cutting and deboning system

Marel’s new extended cutting and deboning system drew a lot of attention to the Marel stand. It greatly improves pig carcass - foreend and hind leg - deboning operations. It gives lower labor costs, higher yield, better quality and longer shelf life. It is now available with integrated logistics.

Automatic case ready solution for quality grading and packing

Marel has added q-vision to its case ready lines. By scanning individual cut products, it is possible to add an extra quality parameter to the case ready packing of products.

The new PremiumFormer

The new PremiumFormer – able to produce any desired type of hamburger – was hugely popular at IFFA, showing its flexibility to the utmost.

Full production control with Innova Food Processing Software

Marel’s IFFA booth also had a dedicated area for Innova Food Processing Software. Monitoring and controlling the production and integrated lines are done with our industry-specific Innova processing software. This gives excellent traceability and production control – for efficient processing in any way.

Get in touch

Our dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.