Every cut counts

For nearly a quarter of a century, pre-portioned fresh meat convenience products have made their way into supermarkets. The industry relies on high-performance portion cutters with well over a thousand cuts per minute to meet the growing global demand for pre-portioned fresh meat. Even artisan-oriented businesses and butcheries that supply several branches or customers in the GM sector can have a high portioning volume that can be automated with a portion cutter. With the right portioning solution, fixed-weight cutlets, steaks, butterfly cuts or even cubes are produced far more profitably and with a significantly improved yield. The hygiene aspect also speaks in favor of automation, as machine-cut portions can be produced virtually contact-free.

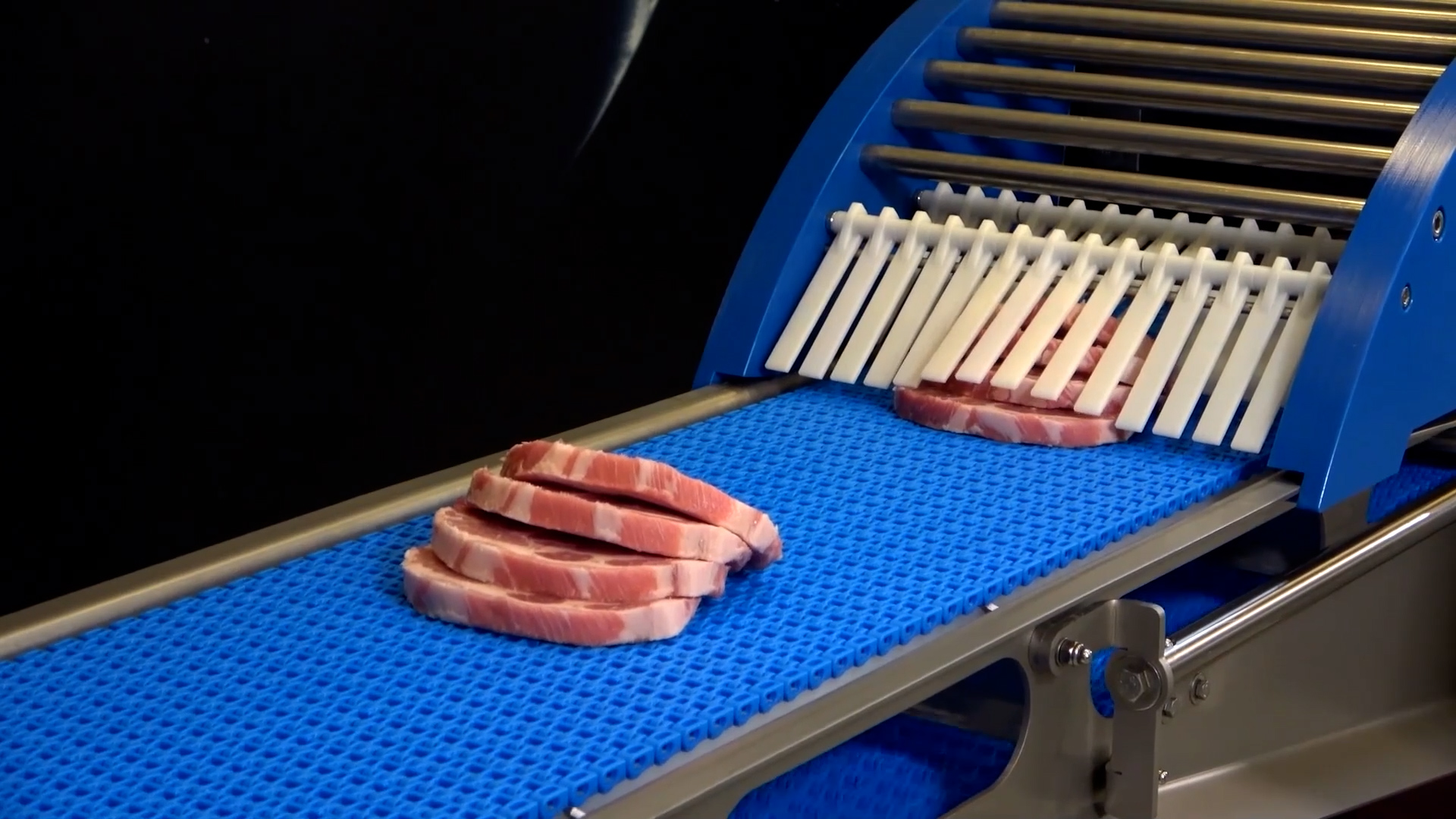

With the V-Cut 160, Marel offers smaller companies a suitable entry-level solution that scores points for high product flexibility, low space requirements, manageable acquisition and operating costs. This means that production processes can be optimized and the product portfolio expanded in a very short time with minimal effort. Especially when labor is expensive or hard to find, the V-Cut 160 can provide valuable services.