Information

Laying the foundation for quality

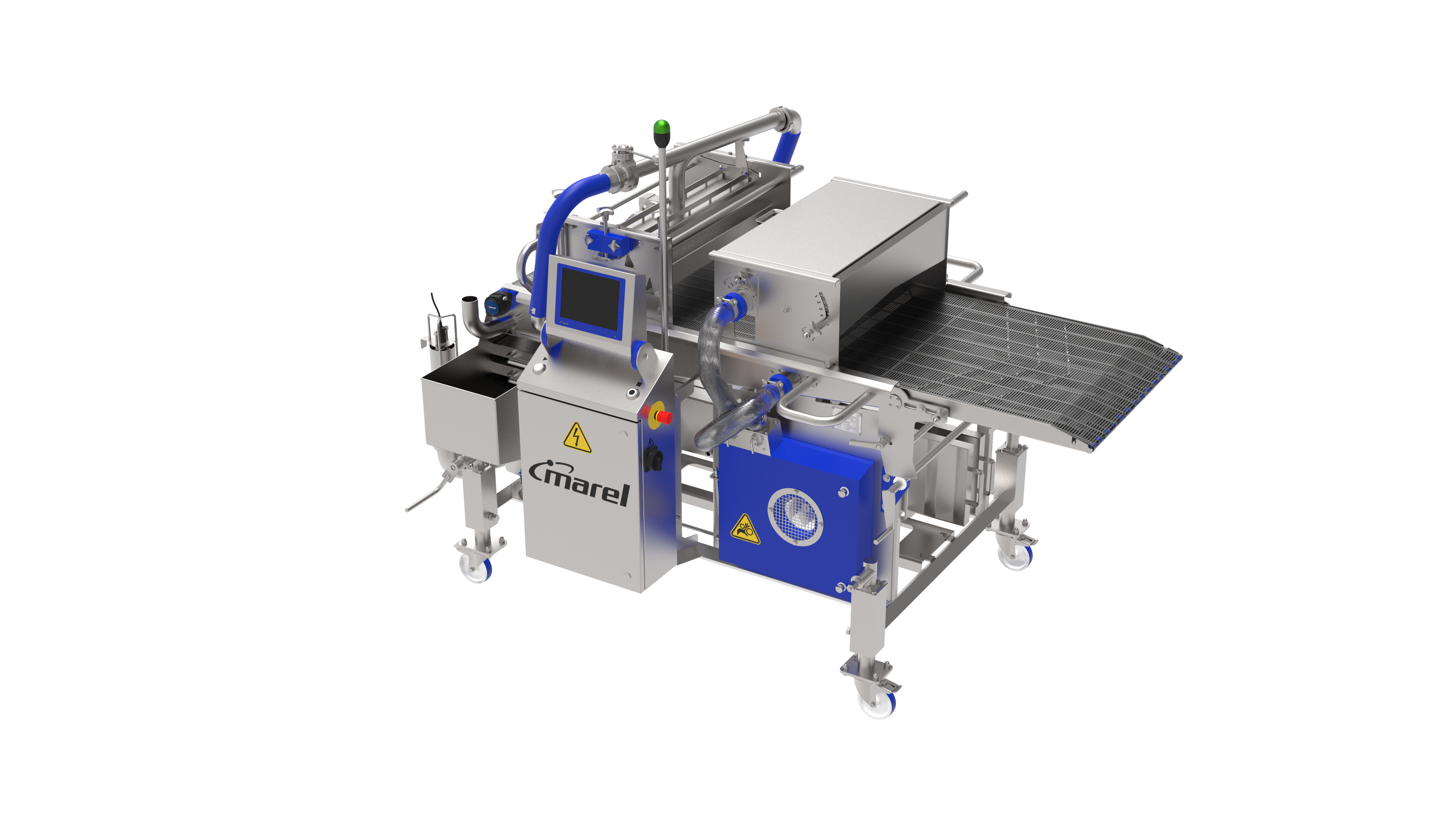

Getting an even and consistent wet coating on every part of a product is key to creating high-quality convenience products. The Active Batter Applicator uses unique technology to ensure an unrivaled, all-around coverage of formed and whole muscle products such as chicken schnitzels, breaded nuggets and tenders. It creates the perfect base for a flawless layer of dry coating.

Perfect top and bottom coverage

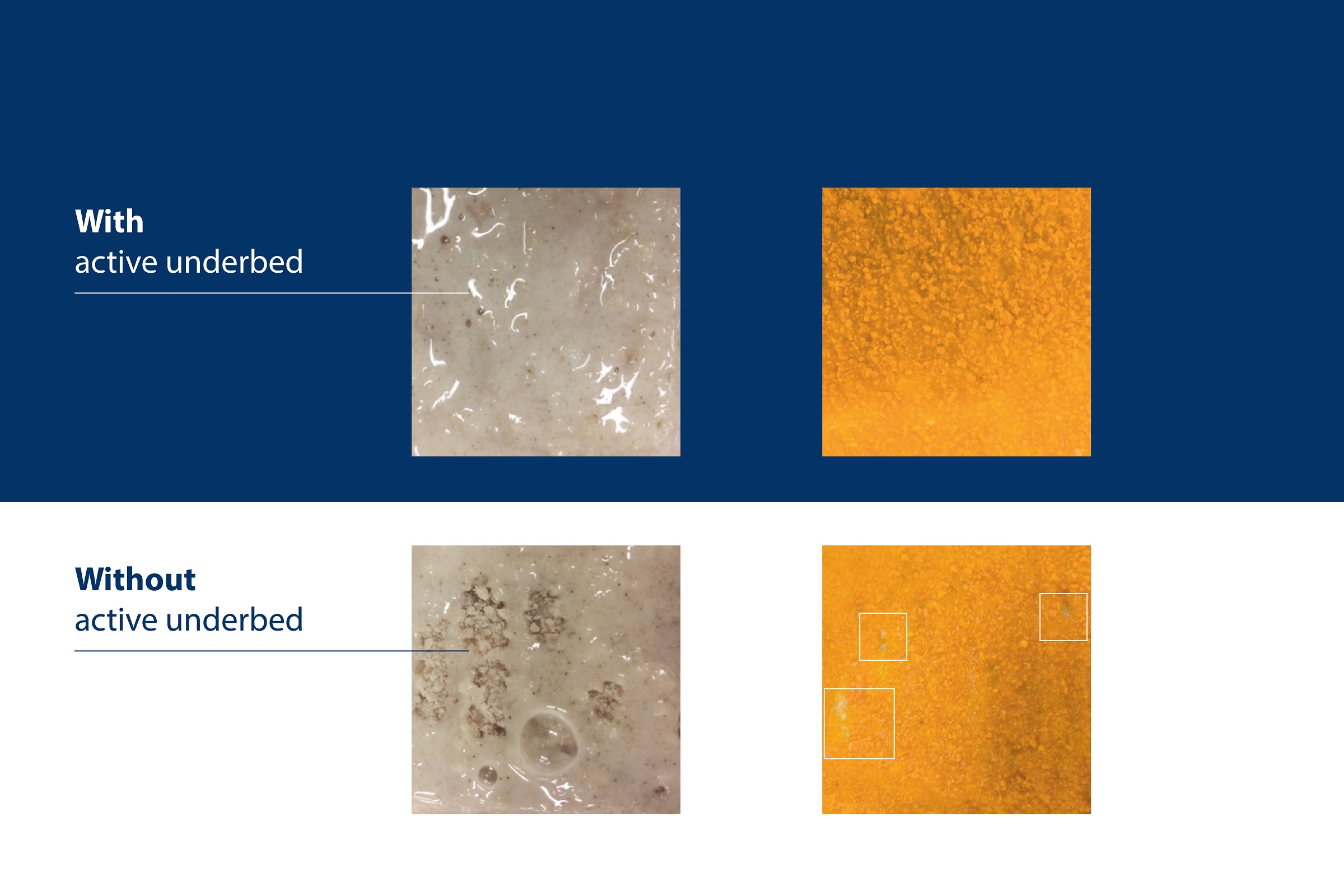

When products enter the machine, they transfer onto a bed of batter rather than directly onto a belt. This unique way of transporting the products through the machine ensures the underside is completely coated and belt marks virtually eliminated. A curtain flow system ensures the top of the product is thoroughly covered to minimize gaps and voids. This results in a more uniform dry coating and ultimately a more valuable product.

Unbeatable pick-up improves yield

When products leave the machine, an air-knife blows off excess batter. Its innovative design ensures equal airflow across the belt to give highly consistent coverage on all products. The better the batter coverage, the better the pick-up giving superior yield.

Supporting every step in the process

The Active Batter Applicator is a crucial step in our full convenience food processing line for chicken schnitzels.