Information

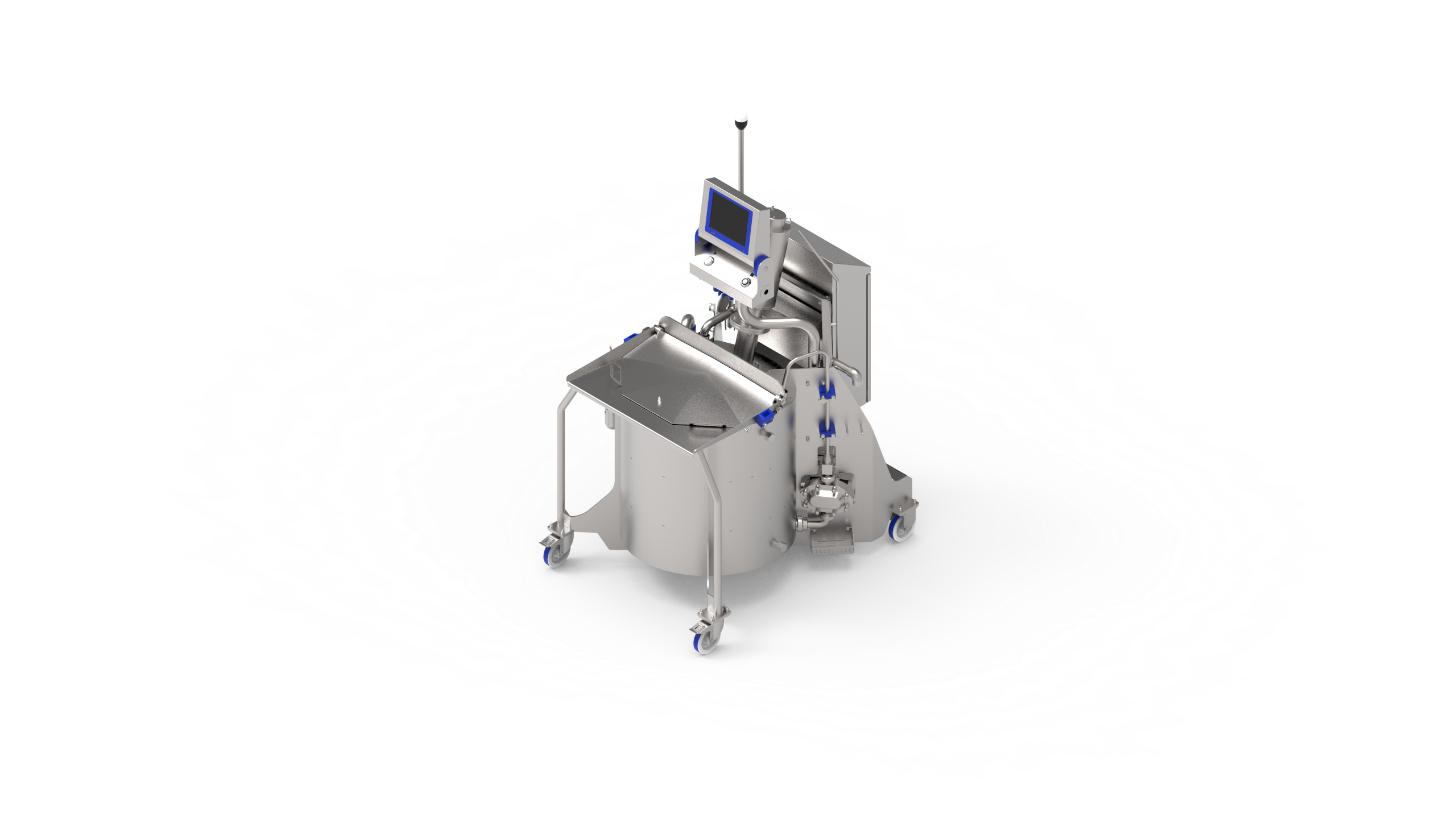

Correct mixing starts with Marel’s Active Mixer. This semi-automatic mixer takes powder and water and turns it into a liquid, homogeneous mixture, which can be tempura or a lower viscosity batter.

The water supply is automated, which ensures a consistent batter and saves labor.

After having completed its task, the Active Mixer feeds the mixture to a batter machine or a tempura machine. The mixer is supplied for normally pumpable mixtures to be used with the Active Batter Applicator or Active Tempura Applicator. In a convenience food line, the Active Mixer would be positioned parallel to one of these machines to feed them directly with the appropriate mixture.

Recipe management

The Active Mixer is fitted with recipe management settings. On the screen, the operator can see which actions are required from him, such as the amount of powder he needs to add and the optimal mixing time. The Active Mixer gives real-time feedback on the batter’s viscosity. When this does not match the recipe settings, the warning light will give a signal. This guarantees a very repeatable and reproducible process.

When connected with Innova Food Processing Software, the Active Mixer can be integrated seamlessly in a larger convenience food line. The overarching software can control and manage the products fed to the machine and knows what the other machines expect from the Active Mixer. The results in the most efficient and profitable production of convenience food.

- Automatic water dosing

- Recipe management settings

- Real-time viscosity feedback

- Stainless steel drives