Information

Coagulation is the process of forming semisolid lumps with the emulsified elements in a liquid by adding coagulants. Flocculants bind these small suspended particles into bigger more stable flock like agglomerates that can be separated easily from the waste water. Therefore, coagulation and flocculation are widely used to bind pollution present in wastewater.

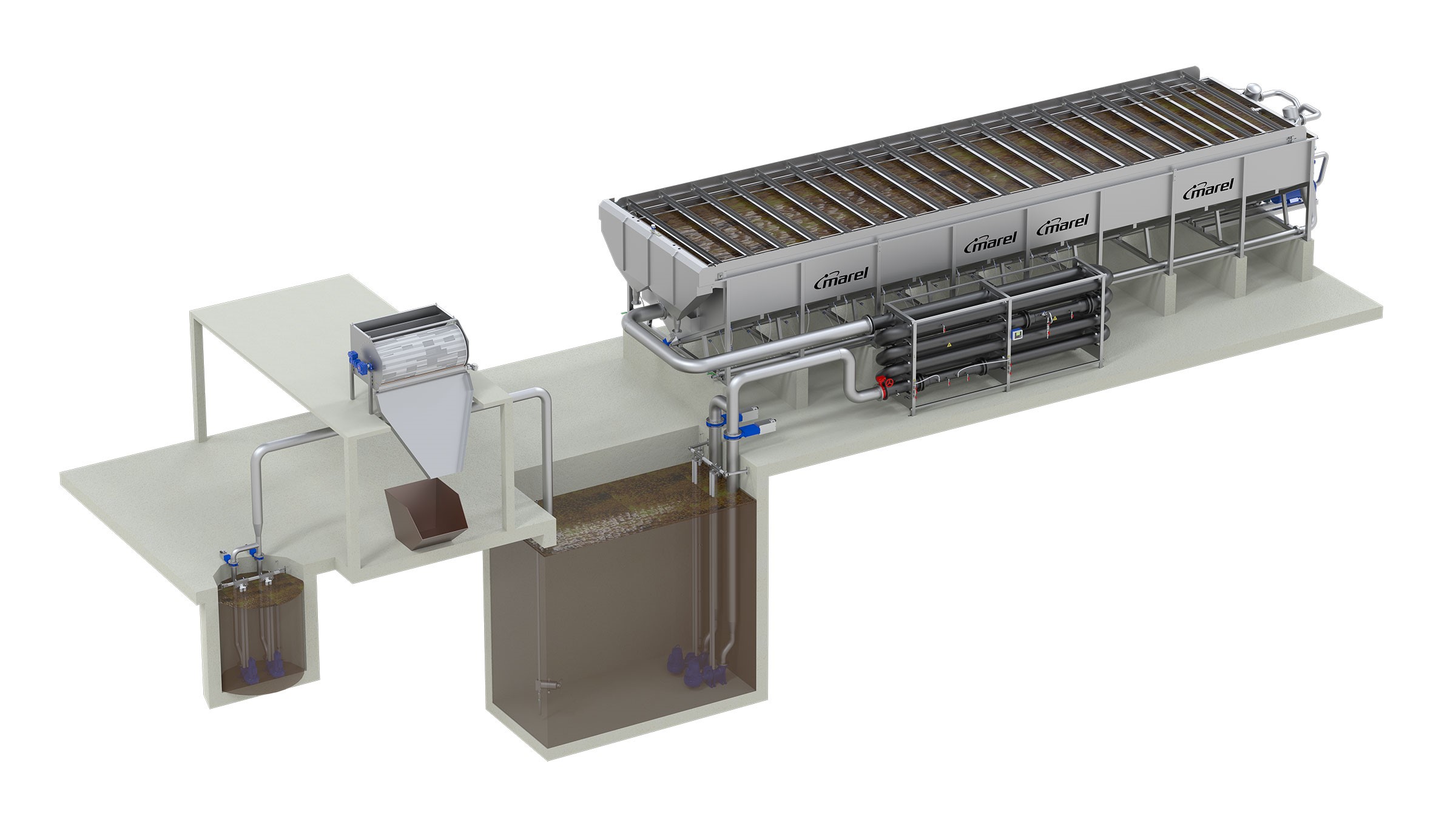

Coagulation Flocculation and Flotation (CFF) is a chemical pre-treatment solution that removes sediment, suspended and emulsified pollution from the wastewater. An equalization basin is often used before the CFF to limit the running costs of the system by levelling peaks in flow rate, pollution, pH values, temperature, etc.

From the equalization basin, the water is pumped to a flocculator. In the flocculator firstly coagulants and then flocculants are dosed to concentrate the emulsified and suspended pollutants in a flock like agglomerate, which can be separated from the water by air flotation. Due to the fact that an acidic coagulant are often used in the process, pH value will drop during coagulation. To maintain an effluent pH in line with the effluent demands, often a neutralizing agent is dosed. There are two types of conventional basin flocculators and plug flow reactor type. The tube flocculator has the advantage of more accurate dosing and very short reaction and mixing times. These factors substantially economize on space, power and chemicals.

The Dissolved Air Flotation unit (DAF) creates micro-air bubbles that become attached to particles, increasing the buoyancy of these particles. The micro-air bubbles usually range in size between 20 and 40 micron. Most of the suspended solids and fat in the wastewater are bigger and micro air bubbles will attach to them, making them rise quickly to the surface of the DAF, where they are removed by a scraper mechanism. Heavy solids just settle a little slower and still accumulate at the bottom of the DAF.