Information

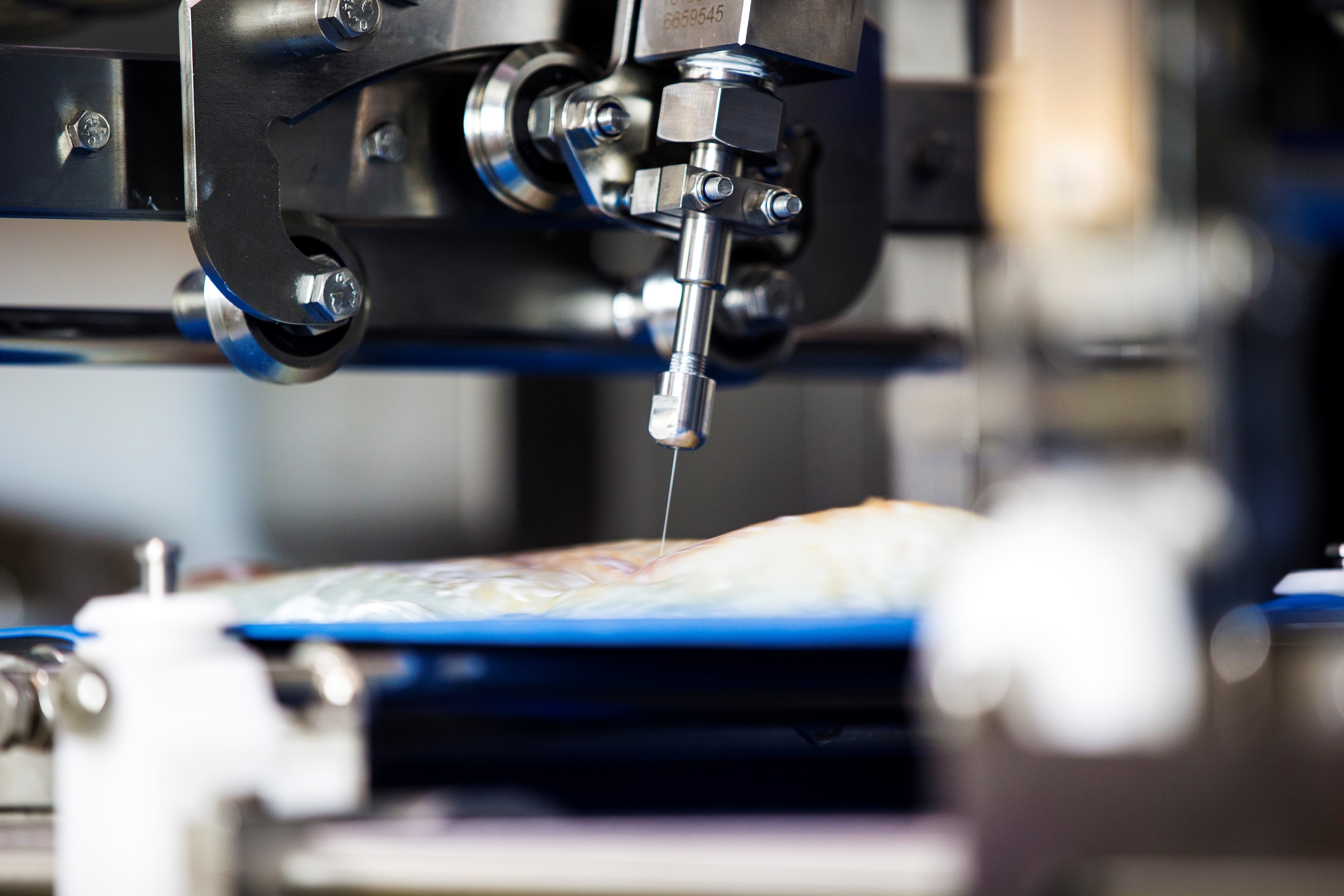

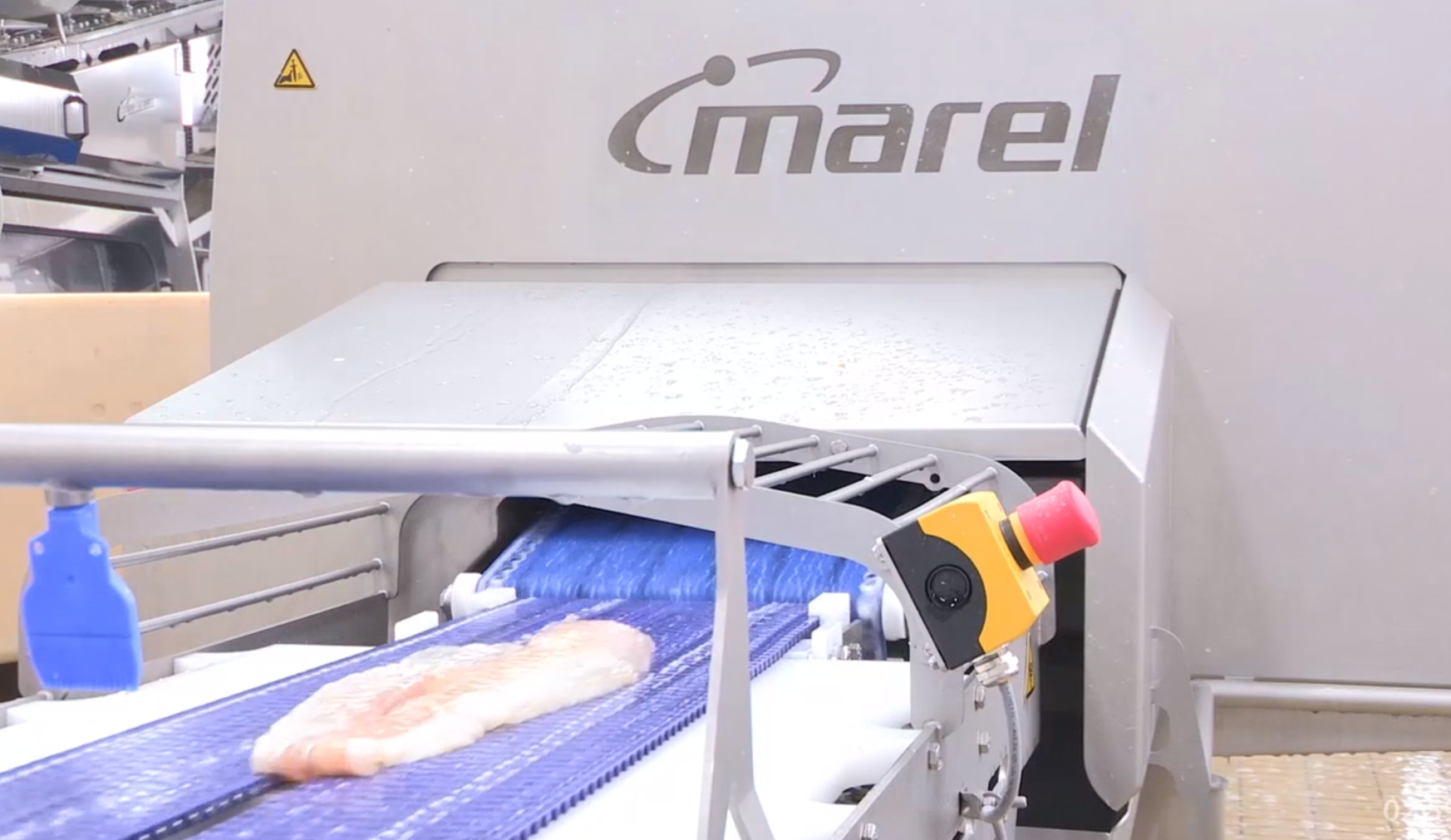

X-ray bone detection and weighing

FleXicut determines the optimal cut configuration and cutting angle by locating the pinbones to an accuracy of 0.2mm, as well as evaluating the weight of each fillet. This ensures added value, with less pinbone material than in manual deboning.

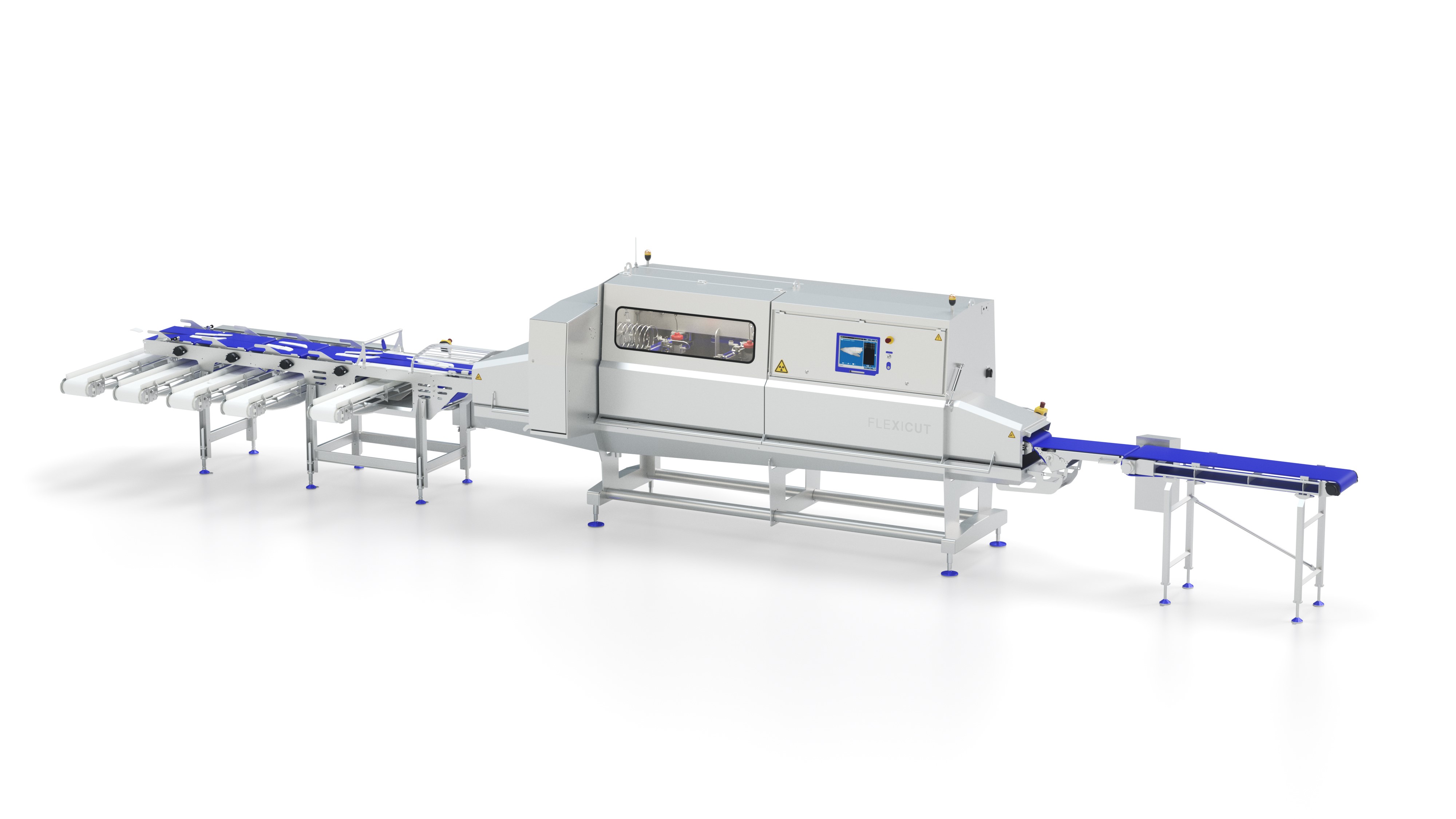

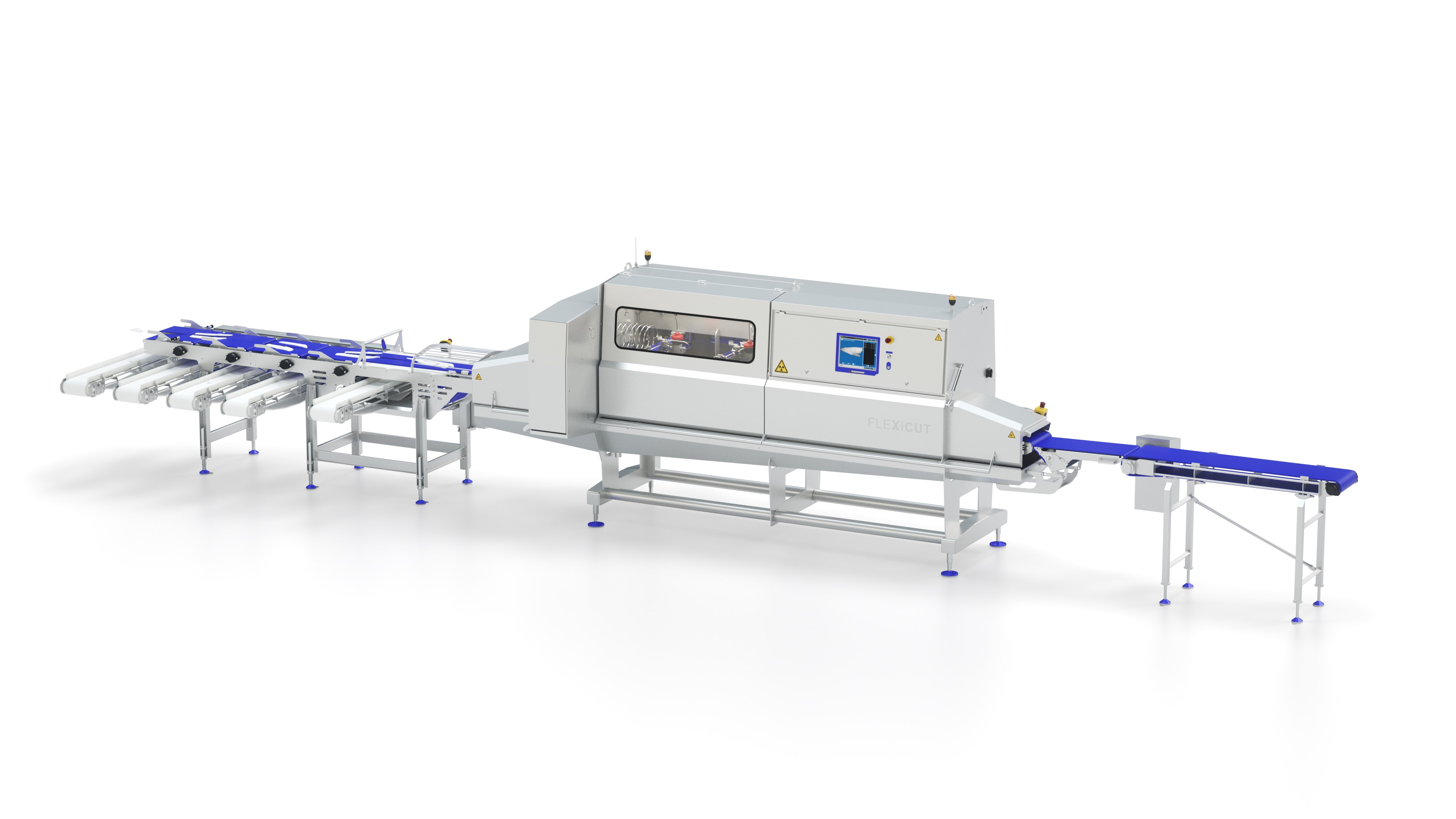

FleXisort intelligent distribution

FleXisort automatically allocates each of the various outputs to different product streams, thereby saving time and increasing efficiency. It also automatically adjusts cutting patterns to achieve the highest value cut.

Real-time monitoring with Innova

Innova enables operators to remotely control FleXicut, monitor the production in real-time and report on actual performance. The data produced via Innova can be viewed in detail via dashboards, allowing operations to be refined quickly and effectively.