Information

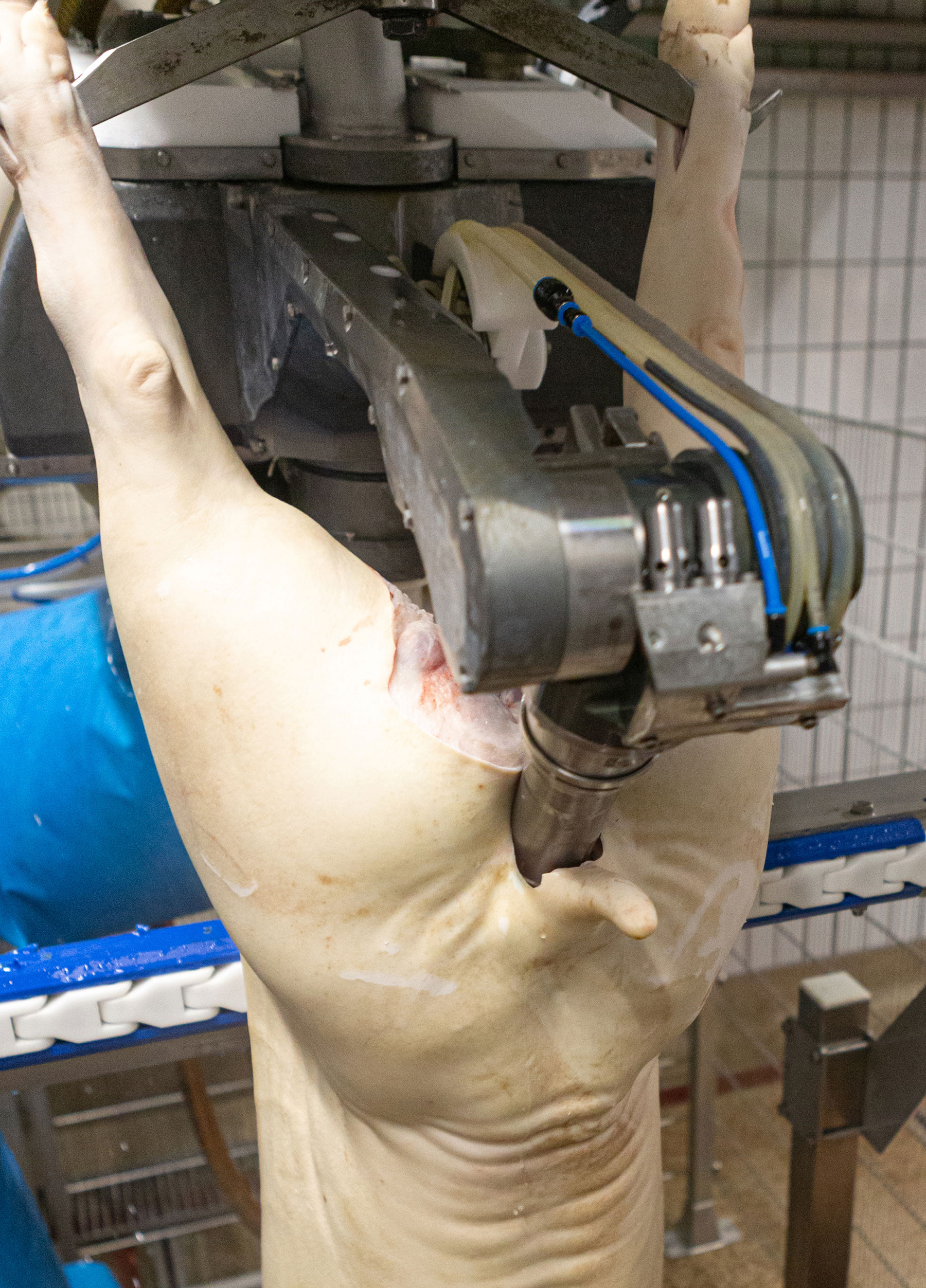

Bung removing is by essence one of the first functions that has to be carried out in this hall, just after the belly opening process. Bung removal (anus drilling) is a complicated process in the slaughter line because it requires a lot of precision and concentration to avoid potential contamination of clean meat.

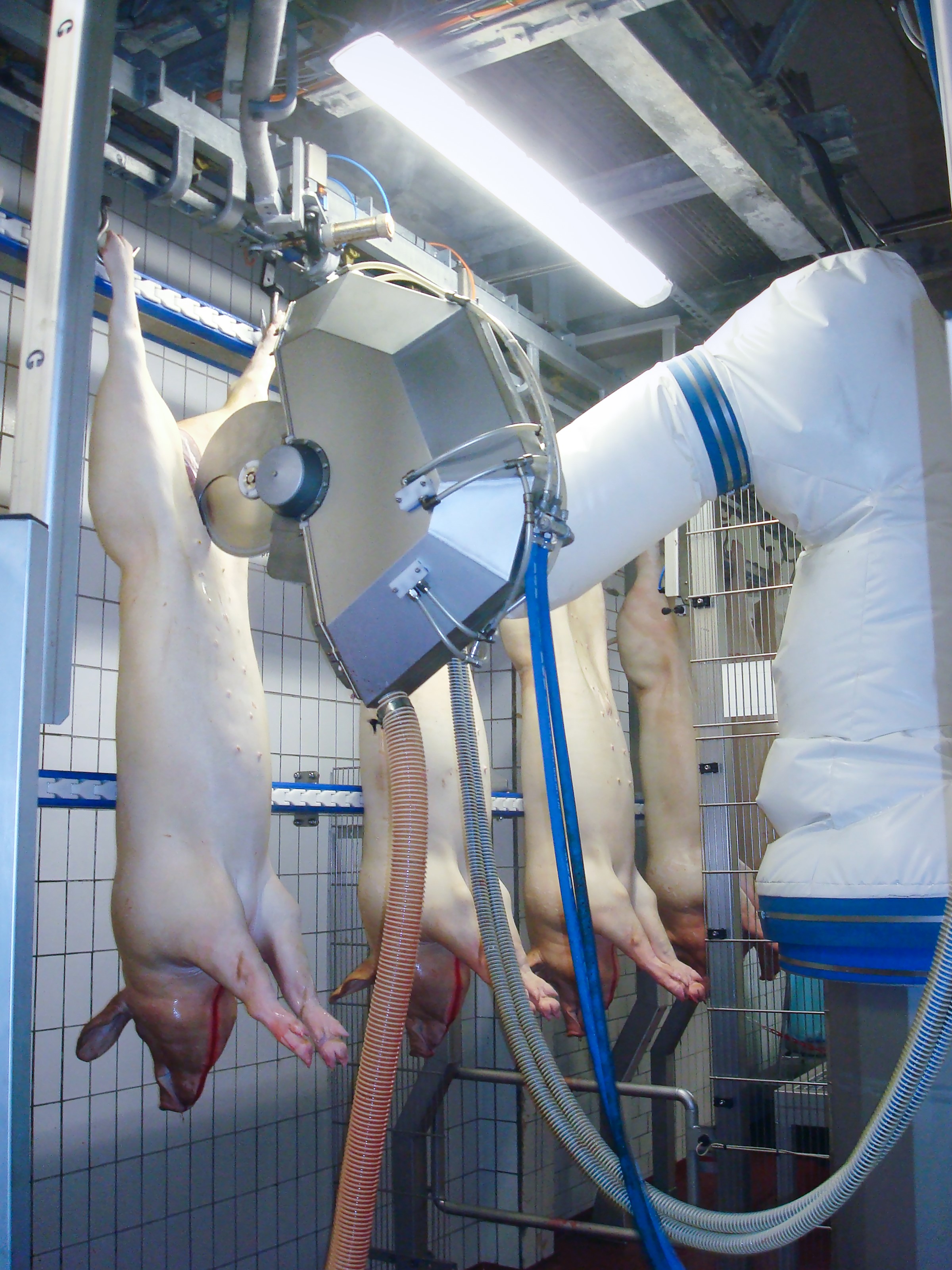

Marel has developed a robotic bung remover, which eliminates the need for persons to perform the job. It is a full-automatic machine, which loosens the fat end of the carcass with unequaled precision and hygiene. It even reaches beyond the performance and capacity attainable by a human operator.

The system allows fully automatic operation and anticipates the increasing demand of an optical clean pelvic channel and a better value of the fat end. Moreover, it replaces the repetitive straining work (RSI injuries), inherent to cutting the bung by hand.

Thanks to high precision 3D cameras, a full and unique image is generated for each carcass, including the identification of whether it is a female or a male. Based on that identification the robot performs the bung removal operation in different ways.

If the pig is a female, the robot enters the bung area from the front of the carcass and pulls the bung to lay with the white organ package. This hugely reduces the risk of contamination of clean meat.

If the scanned carcass is a male, the robot enters the bung area the same way but leaves it in the bung channel.

Patented "TwinTool" for M-Line robots

Because the process of bung removal takes place in the production area before clean inspection, there is a need to sterilize the tools after each operation.

This means that the operator has to sterilize the bung remover in hot water after each individual bung removal.

With the M-Line Bung Remover this sterilization operation has become automatic. The robot incorporates Marel’s patented “Twin Tool” sterilizing technology, which means that while one tool is in operation another similar tool is being sterilized inside a cabinet at the head of the robot. Thus, no manual sterilization is needed with the M-Line robots.

- Efficient sterilization

- Hygiene and food safety

- Increased shelf life

- No need to sharpen or change tool during production

- No action required during day

The M-Line Bung Remover has a capacity of 650 carcasses per hour.