Information

Energy-saving immersion chilling of carcasses

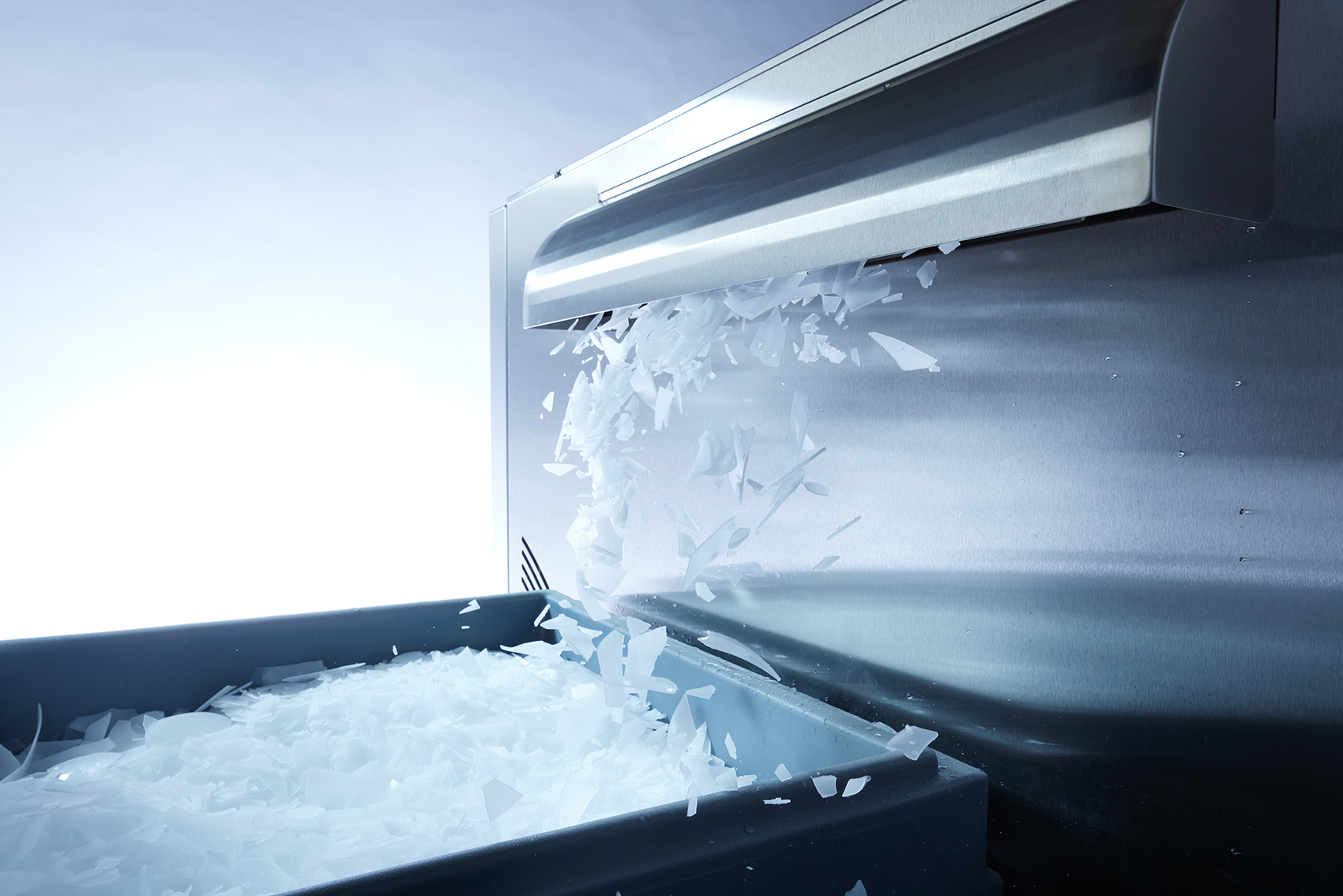

For product safety, poultry carcasses have to be chilled to reduce their temperatures from approximately +40° to +4°C. In immersion chilling, carcasses are moved through tanks containing a mixture of water and flake ice. Adding ice to the chilling water helps to reduce the temperature quickly and in a highly energy-efficient way. This can be helpful for high ambient and water-supply temperatures.

Hygienic and sustainable flake ice

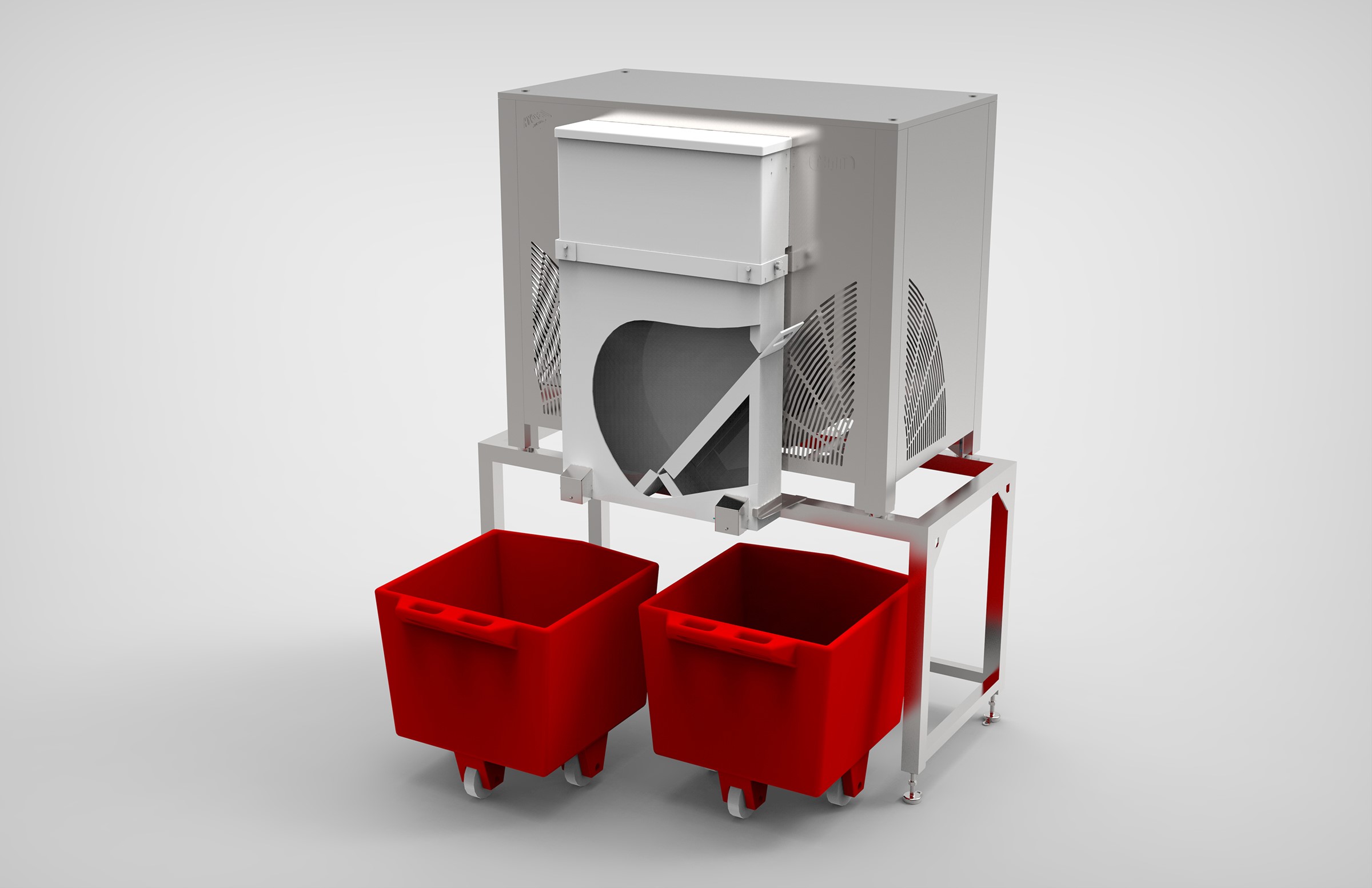

Our focus is firmly on hygienic ice production, which lets you create ice of the highest quality. MAJA flake ice machines are labeled HY-GEN protected. This stands for excellent sanitary conditions. We also take pride in being the leading manufacturer in sustainable ice producing solutions. We use natural, eco- friendly refrigerants, which help you to reduce your carbon footprint.

Decades of knowledge and experience

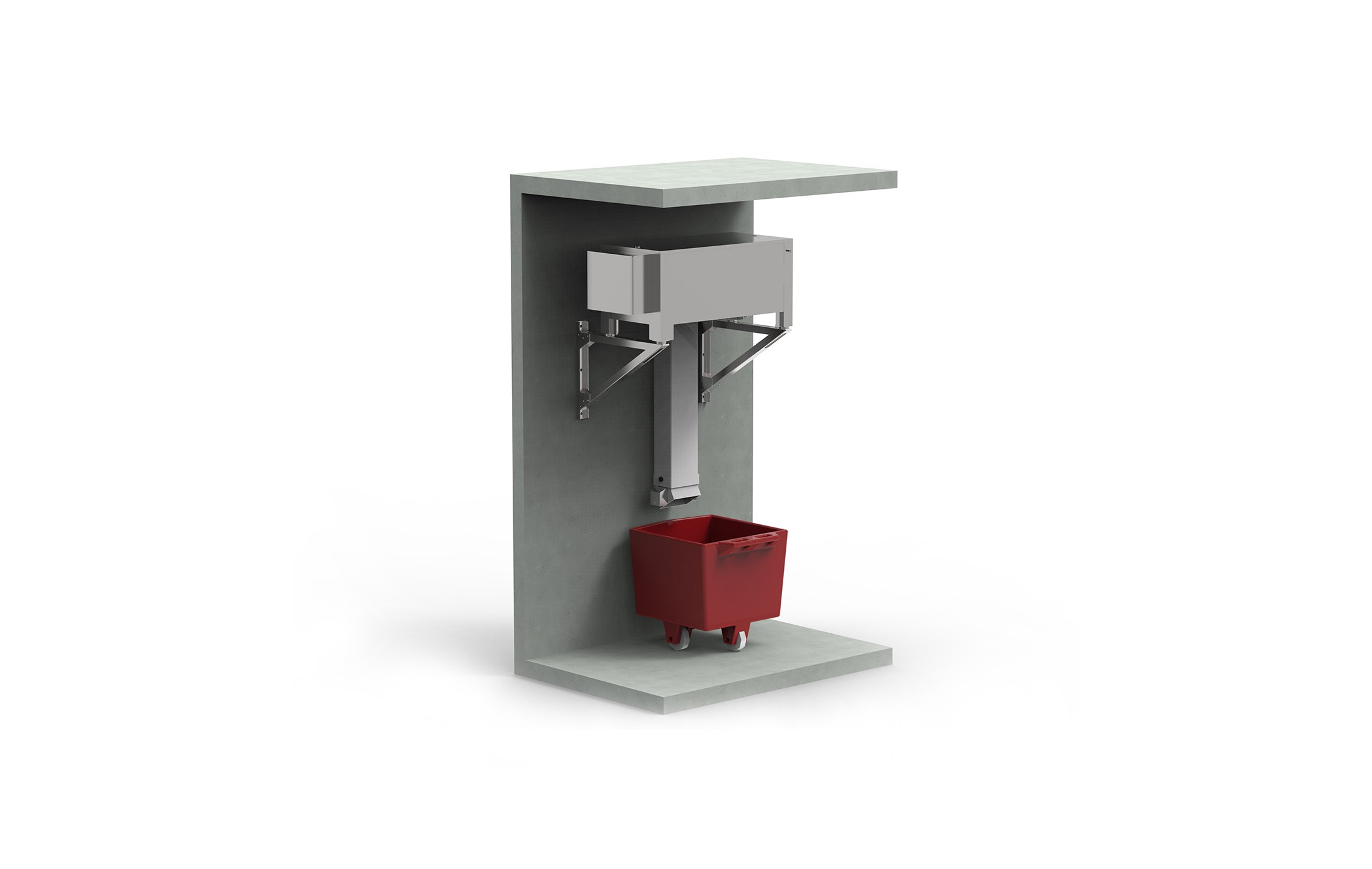

For more than 70 years, we’ve been supplying highly reliable and energy efficient ice machines to the meat industry. Our many decades of knowledge and experience make us the ideal partner for all your needs in ice production, handling, transport, storage and batching.