Information

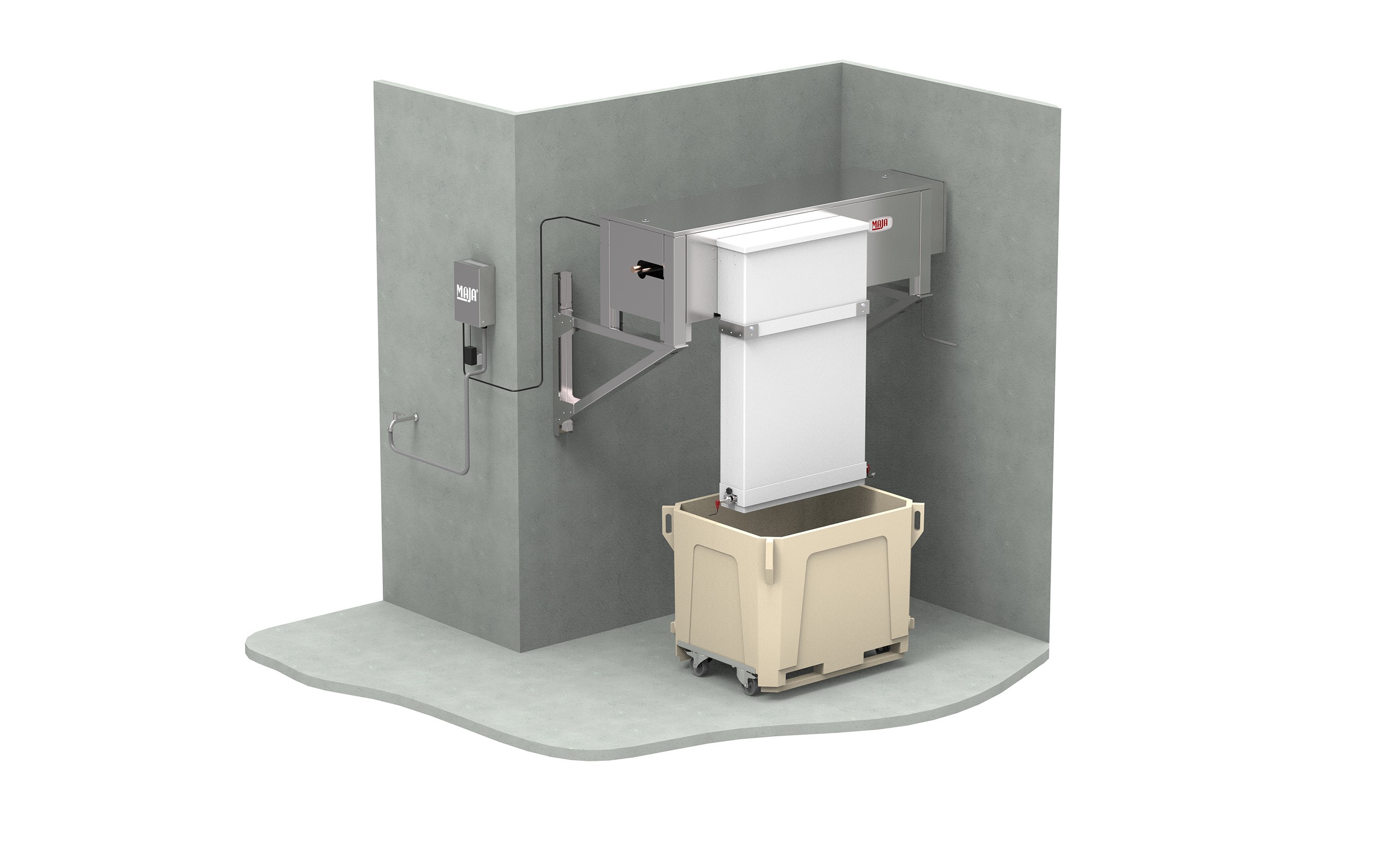

The flake ice machines MAJA-RVH offer a wide choice of ice-producing units with ice output ranging from 250kg up to 12,000kg every 24 hours. Without condensing units, they are designed for integration in multi compressor refrigeration circuits, used by the meat and fish industry, in bakeries or supermarkets, but also in various non-food applications.

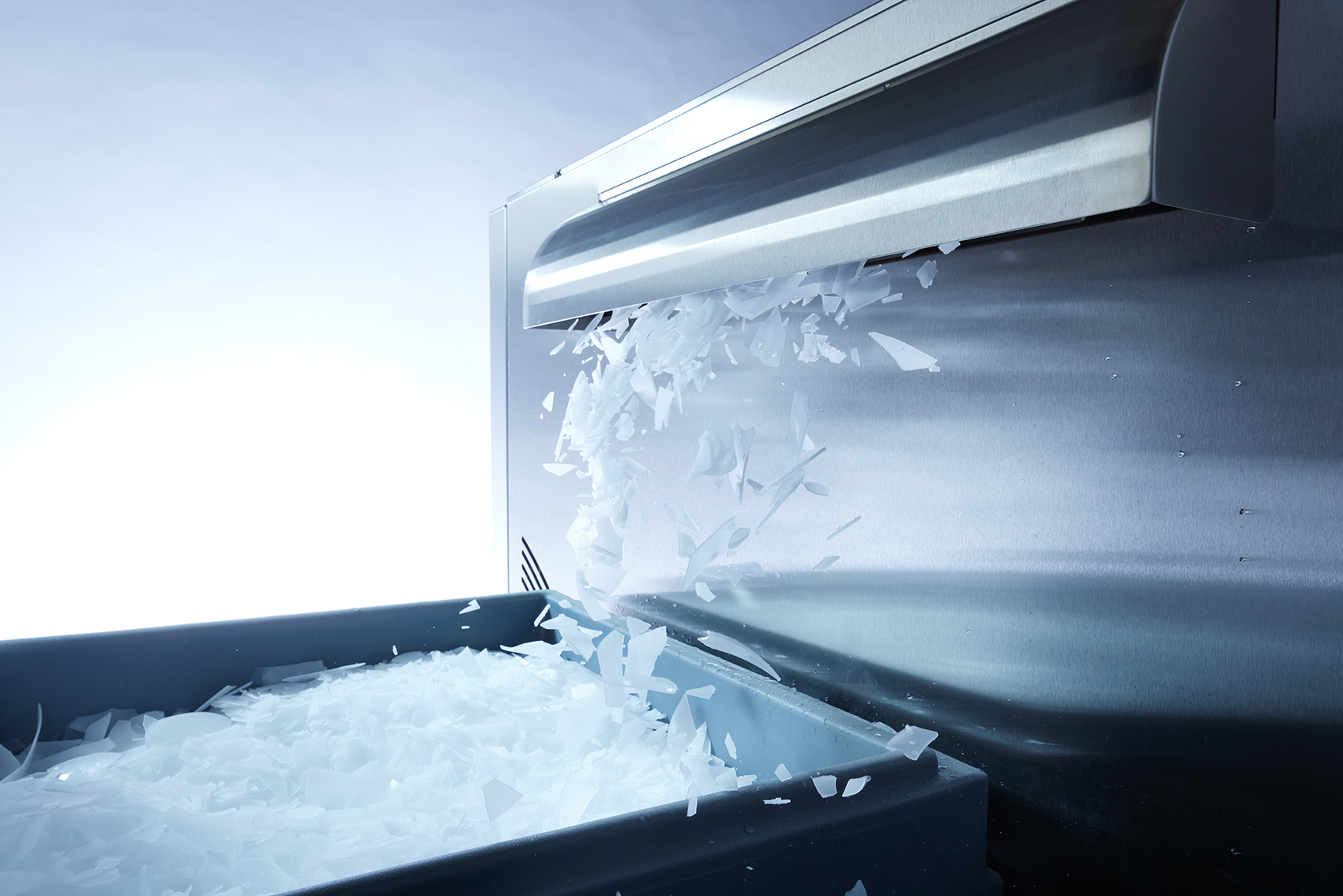

Hygienic, food-safe ice production

MAJA flake ice machines are labeled HY-GEN protected. This stands for excellent sanitary conditions:

- Easy access to cleaning relevant parts from all sides, without the use of tools

- Easily removable, round-shaped plastic water tank

- Water tank without built-in parts, angles, edges and screws, allowing easy and thorough cleaning

- Automatic water pipe rinsing after 24 hours without ice production

- Special hygiene advantages in accordance with the German drinking water regulations

Refrigeration

- For connection to (separate) external refrigeration units or multi compressor refrigeration systems

- Designed for operation with fluorinated greenhouse gases R449A (GWP 1397); other refrigerants on demand

Easy operation – convenient ice handling

- Easy operation by control panel ON/OFF for remote operation

- Control panels with program functions are optionally available

- Reliable SPS control unit

- Solid machine structure, frame and housing in stainless steel