Information

The flake ice machines MAJA RVH-NH3 without condensing unit are designed for direct operation with an ammonia/R717 multi compressor refrigeration unit for ecological and sustainable ice production projects.

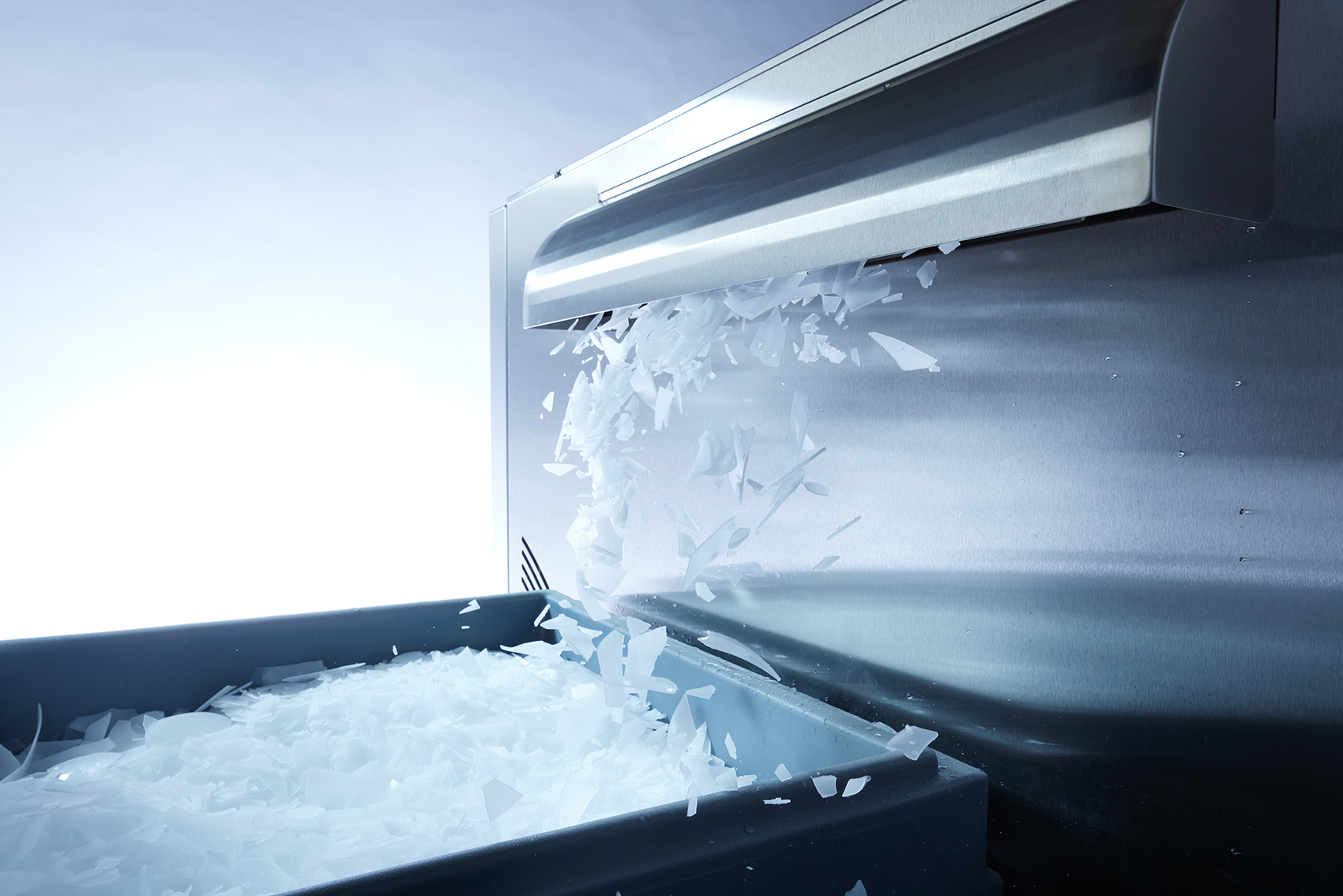

Hygienic, food-safe ice production

MAJA flake ice machines are labeled HY-GEN protected. This stands for excellent sanitary conditions:

- Easy access to cleaning relevant parts from all sides without the use of tools

- Easily removable, round plastic water tank

- Water tank without built-in parts, angles, edges and screws, allowing for easy and thorough cleaning

- Automatic water pipe rinsing after 24 hours without ice production

- Special hygiene advantages in accordance with the German drinking water regulations

Refrigeration

- Optimum energy efficiency for increased power density. Compared to traditional refrigerants, for example, R404A, the direct ammonia operation brings more power density, thus increasing ice output compared with other machines of the same scale

- The RVH 12000 NH3 consists of two separately operated rotating evaporator units. Giving the advantages of individual control of ice output according to varying needs and high operational safety

- Electronic evaporation pressure regulation for optimum efficiency

- Eco-friendly flake ice production and excellent ecological impact by using natural refrigerant

- R717 (ammonia/NH3) for flake ice production. R717 consists of the elements nitrogen and hydrogen, which are natural parts of the atmosphere

- No influence on the destruction of the ozone layer and no influence on the greenhouse effect. Ozone depletion potential ODP=0, Global warming potential GWP=0

- Installation conditions: Existing R717 multi compressor refrigeration unit working in pump operation, meaning the refrigerant becomes liquid and circulates

- Ammonia temperature is approximately -30°C.

- Pump pressure 2-4 bar.

- High safety standard. An integrated safety system with a gas detector, automatic cutoff and blockage in case of leakage

Easy operation for convenient ice handling

- Easily operated by the Control Panel Touch (control unit with touch display):

Individual placing of the control unit - A timer function for freely programmable production and cleaning cycles, with an optional MAJA-SCS self-cleaning system, to ensure the right quantity of fresh flake ice at your disposal at the right time