Information

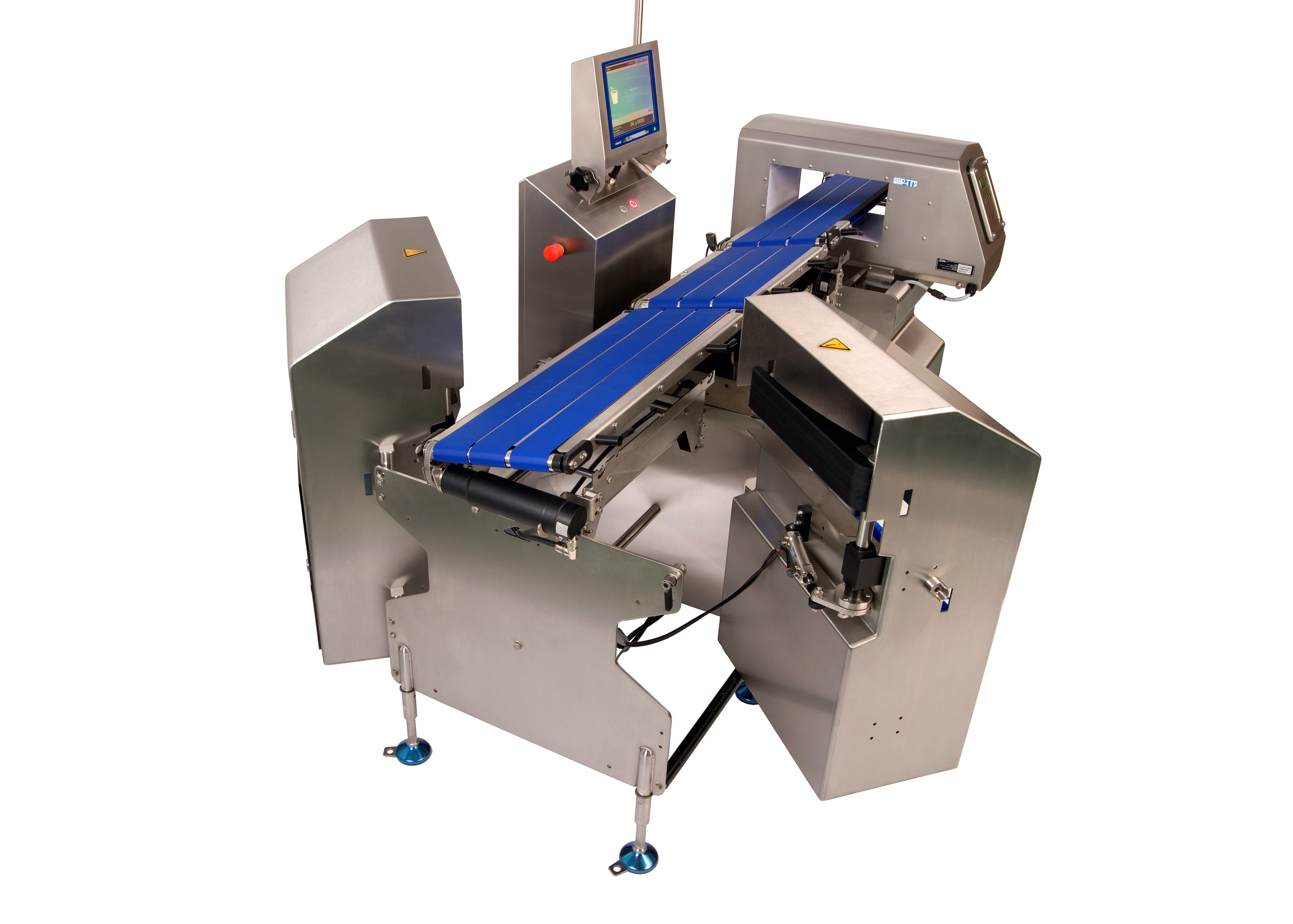

The MCheck 2 Checkweigher combines high levels of accuracy with flexibility and capacity, making it the ideal choice for any food processing company—both in wet and dry production environments and end-of-line applications.

Whether you need a process weigher for monitoring and optimizing the accuracy of the process equipment in your factory, or a checkweigher to ensure compliance with weight legislation, MCheck 2 will meet your requirements.

MCheck 2 can weigh before and after a process for yield calculation and check the number of items in a package based on weight. The machine can also feed information forward to a dosing system to ensure accurate package weights.

- Detects metal and removes contaminated packs

- Withstand an intense high-pressure wash-down to IP69 standards

- Available in different modular configurations

- An optional trend light indicator

- Optional single and multi-frequency metal detection

- A choice of single pusher, flipper, twin reverse flipper or drop flap reject