Information

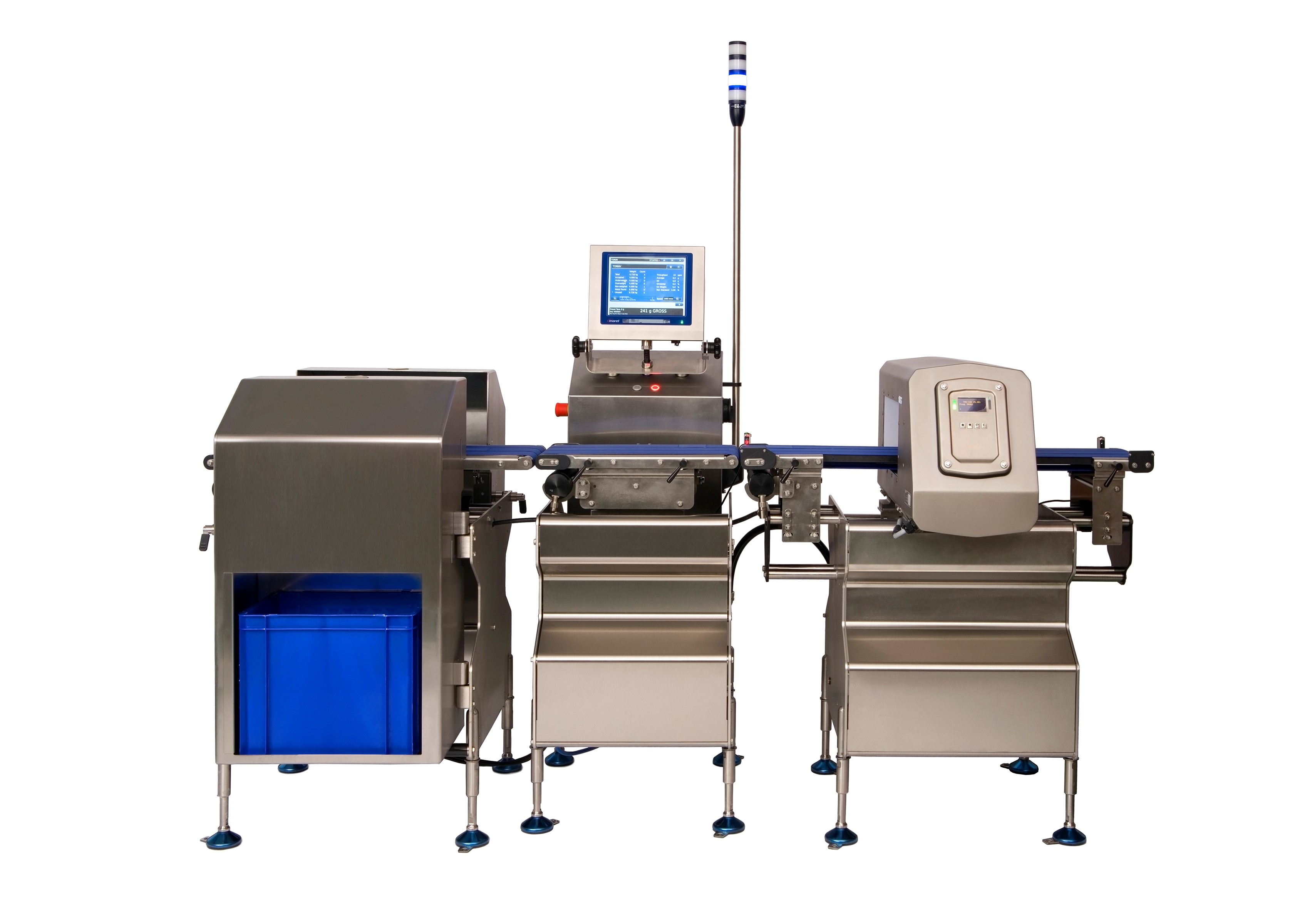

Marel’s MCheck 2 Checkweigher combines high levels of accuracy with flexibility and capacity, making it the ideal choice for any food processing company – with approval for process and end of line applications.

The checkweigher can monitor and optimize the accuracy of processing equipment, and ensure compliance with weight legislation across a wide range of products.

- Optional single and multi-frequency metal detection ensures quality control on single and multi-product lines.

- A choice of single pusher, flipper, twin reverse flipper or drop flap reject with reject confirmation reliably removes off weight and metal contaminated products from the product flow for maximum product safety.

- Fully approved remote access / display option.

- An optional trend light indicator provides a visual representation of average product weight over a specified number of packs or products.