Information

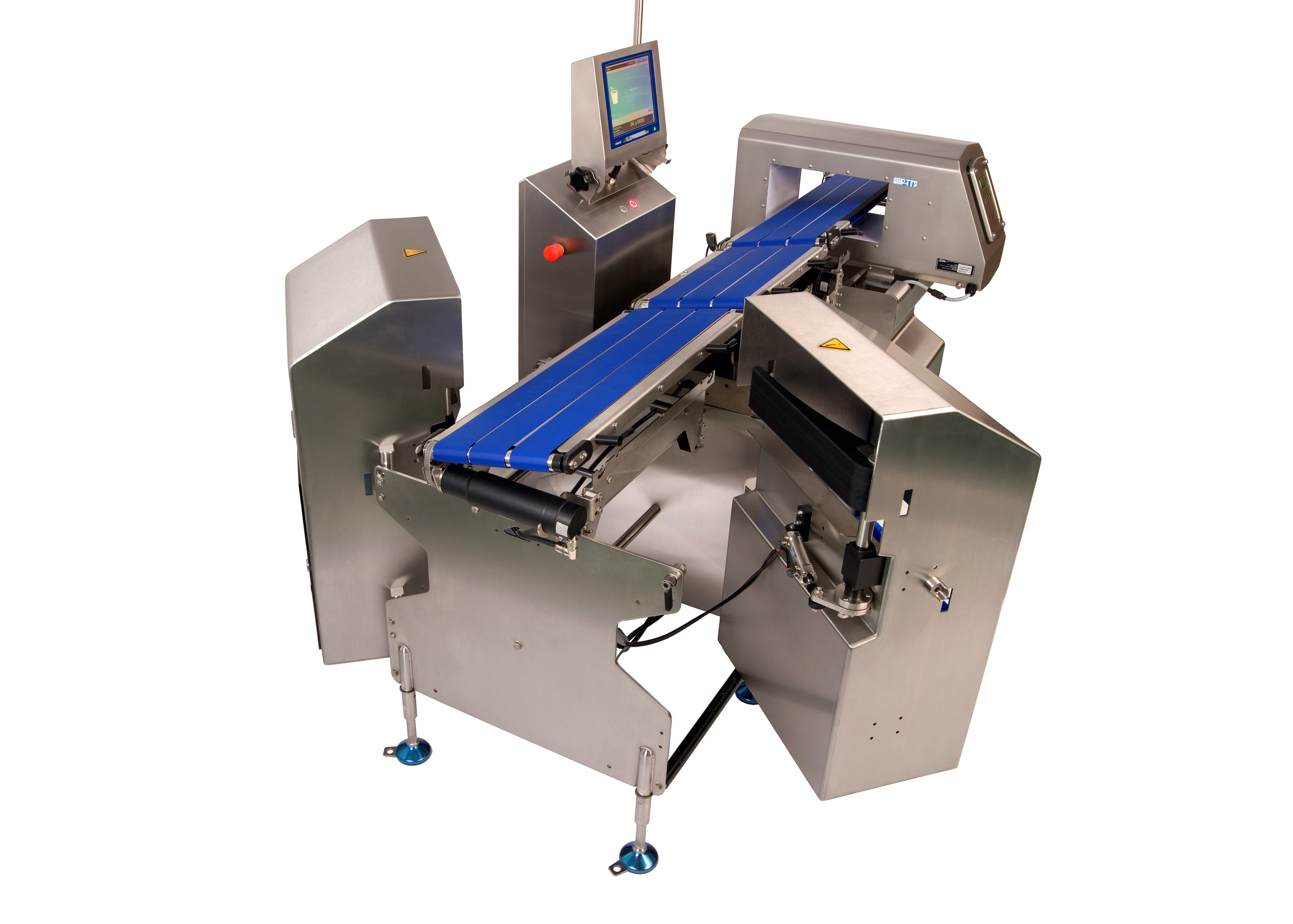

MCheck 2

MCheck 2 combines high levels of accuracy with flexibility and capacity, making it the ideal choice for any food processing company – both in wet and dry production environments and end-of-line applications.

Whether you need a process-weigher for monitoring and optimizing the accuracy of the process equipment in your factory, or a checkweigher to ensure compliance with weight legislation, MCheck 2 will meet your requirements.

Compliance with weight legislation

MCheck 2 weighs and checks a wide variety of indexed packs or pieces in a continuous flow against predetermined limits. It prevents underweight and/or overweight packages and rejects ‘out of spec’ packs while ensuring compliance with weight legislation for sealed packs.

Line optimization

MCheck 2 can weigh before and after a process for yield calculation and check the number of items in a package based on weight. The machine can also feed information forward to a dosing system to ensure accurate package weights.

Food safety and hygiene

MCheck 2 features a range of metal detection and reject options which remove off weight and metal contaminated packs from the product flow. Single and twin reject confirmation, combined with lockable reject bins, ensures food safety and quality control.

Full washdown

The MCheck 2 can withstand an intense high-pressure washdown to IP69 standards, thanks to its sturdy and easy to clean design.

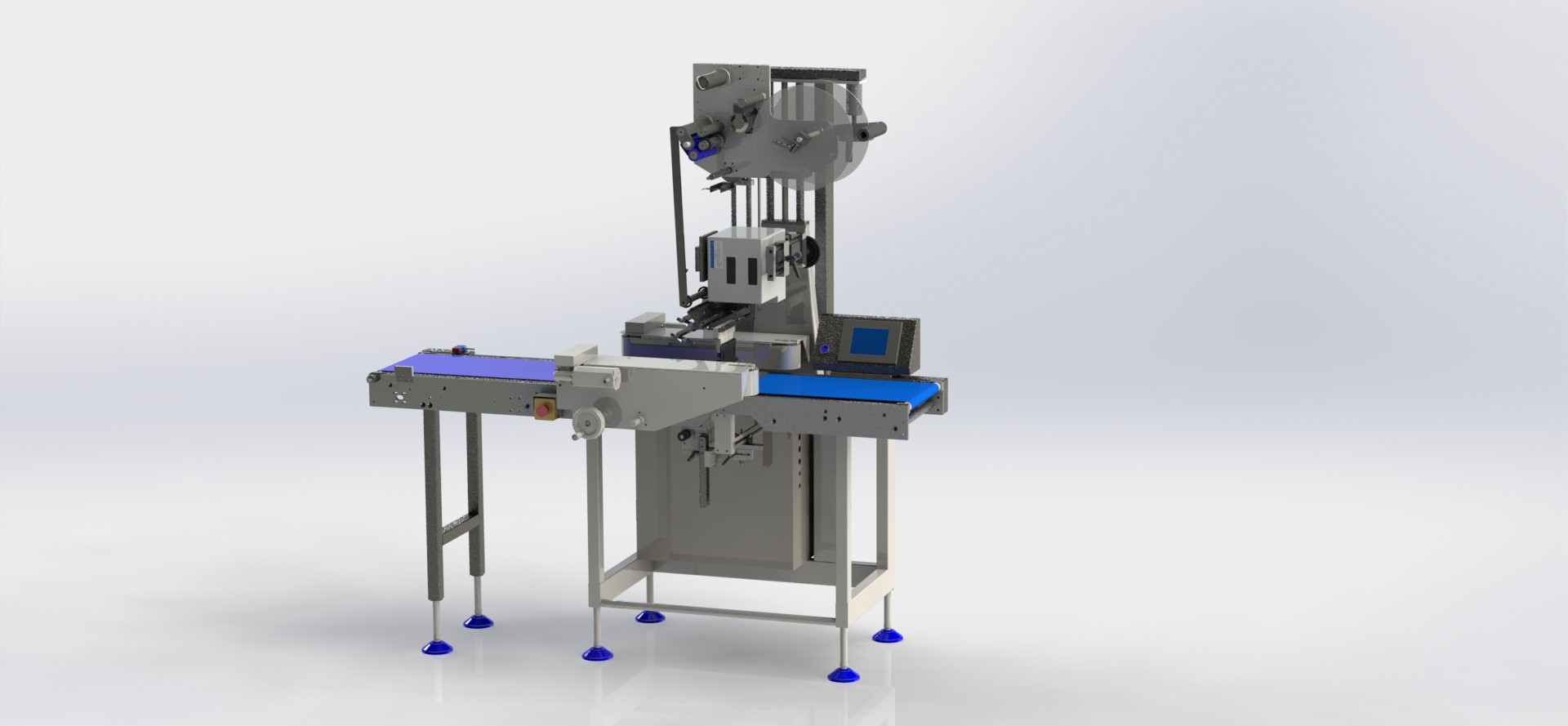

- Available in different modular configurations

- An optional trend light indicator

- Optional single and multi-frequency metal detection

- A choice of single pusher, flipper, twin reverse flipper or drop flap reject

- Fully approved remote access and display option