Information

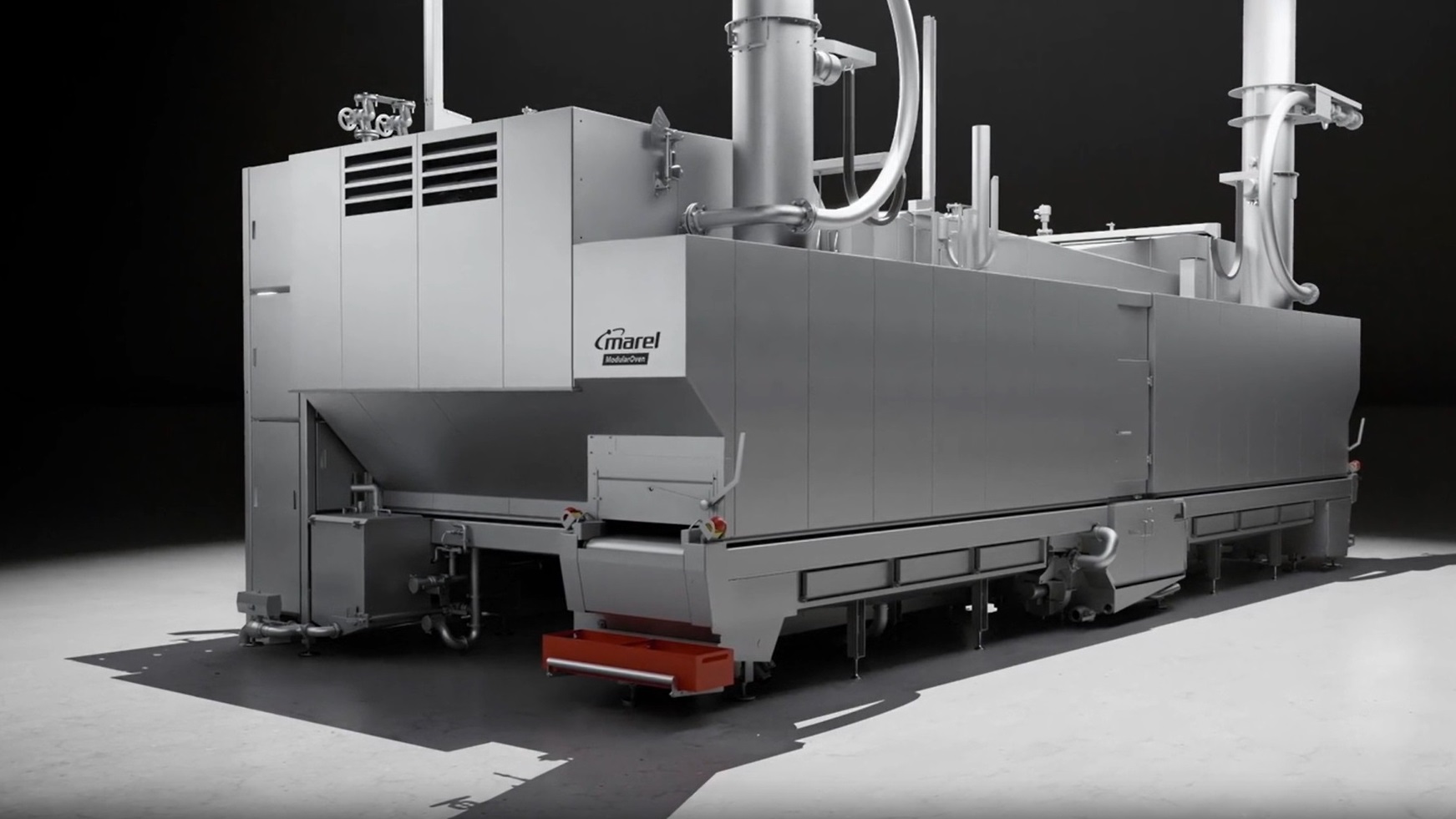

The ModularOven offers the perfect flexibility and control of the production process to create the ultimate end product. With high capacity and adaptability, the ModularOven is excellent for innovative new products and is proven successful for processing a wide range of steam-cooked, marinated, coated and roasted products.

Achieving the right appearance, texture, flavor and bite for the most enjoyable eating experience relies heavily on the cooking parameters. With the ModularOven, you can maximize control of the process. This allows you to obtain the desired degree of crispness, browning and juiciness, while optimizing yield and capacity.

SEPARATE CLIMATE ZONES

The ModularOven is Marel's biggest oven system, consisting of two towers with separate controls for temperature, dew point and air speed, which offer the desired variable functionality for steaming, cooking or roasting in two completely separated climate zones.

The power of two towers combined gives the ModularOven its high capacity and versatility. For example, one tower may be used for high dew point steaming, followed up with high temperature, low dew point cooking in the other tower.

PRODUCT SAFETY

The design of the ModularOven provides a greater level of food safety by being able to control temperature variation throughout the complete oven. An optimal environment is created across the belt, all around the product, even products with varying thickness. This allows for the desired end core temperature averages to be lowered, so better yield is obtained.

- Two separate climate zones

- Optimal airflow around the product on all layers of the conveyor belt

- Lower end core temperature averages needed

- Substantial energy savings

- Short cooking times

- Suitable for a wide range of poultry products, e.g. whole chickens, fillets, roasted duck, nuggets, hamburgers, sausages

- Ease of cleaning and ease of operation

- Easily operated from a menu-based touch screen

- Integrated belt-washer