Information

As a poultry processor, you’re always looking for ways to make the most value of every gram of meat. Implementing a Marel Poultry MSM Line could be the solution for you, as there’s a lot of market potential to capitalize on added value Mechanically Separated Meat (MSM).

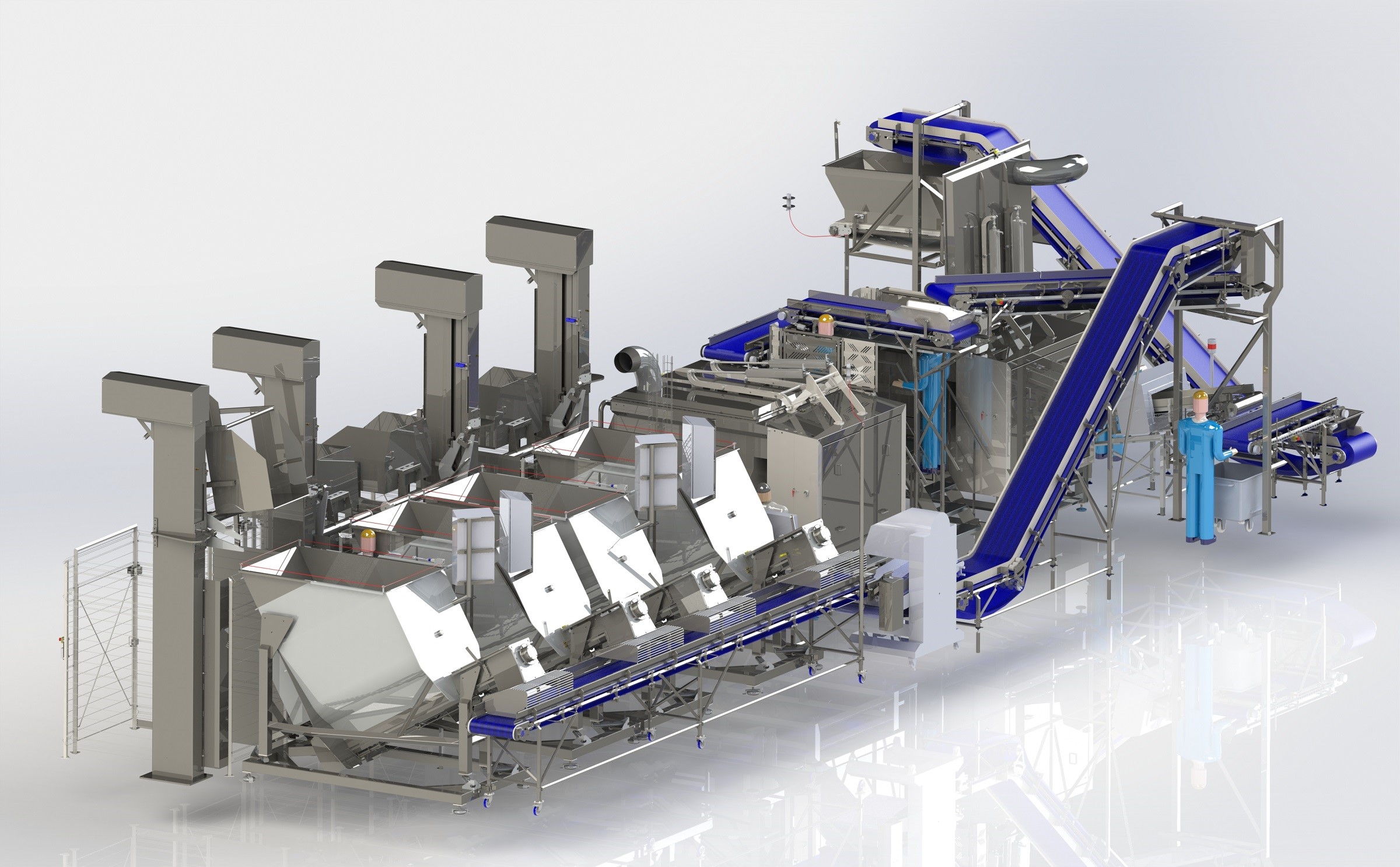

Typically, you’ll have 4 different broiler carcass components after your cut-up and deboning lines –breast caps, front halves, front back pieces, and rear back pieces. These four components can be the base material to make up high-quality MSM meat. You’ll need to mix the four components to get a meat mass with predefined fat content, a precondition for correct followup processes. Manual mixing is simply impossible; it is not accurate enough to get a consistent fat percentage. That’s why Marel has developed a logistic automated solution for this kind of meat preparation.

How does the process work?

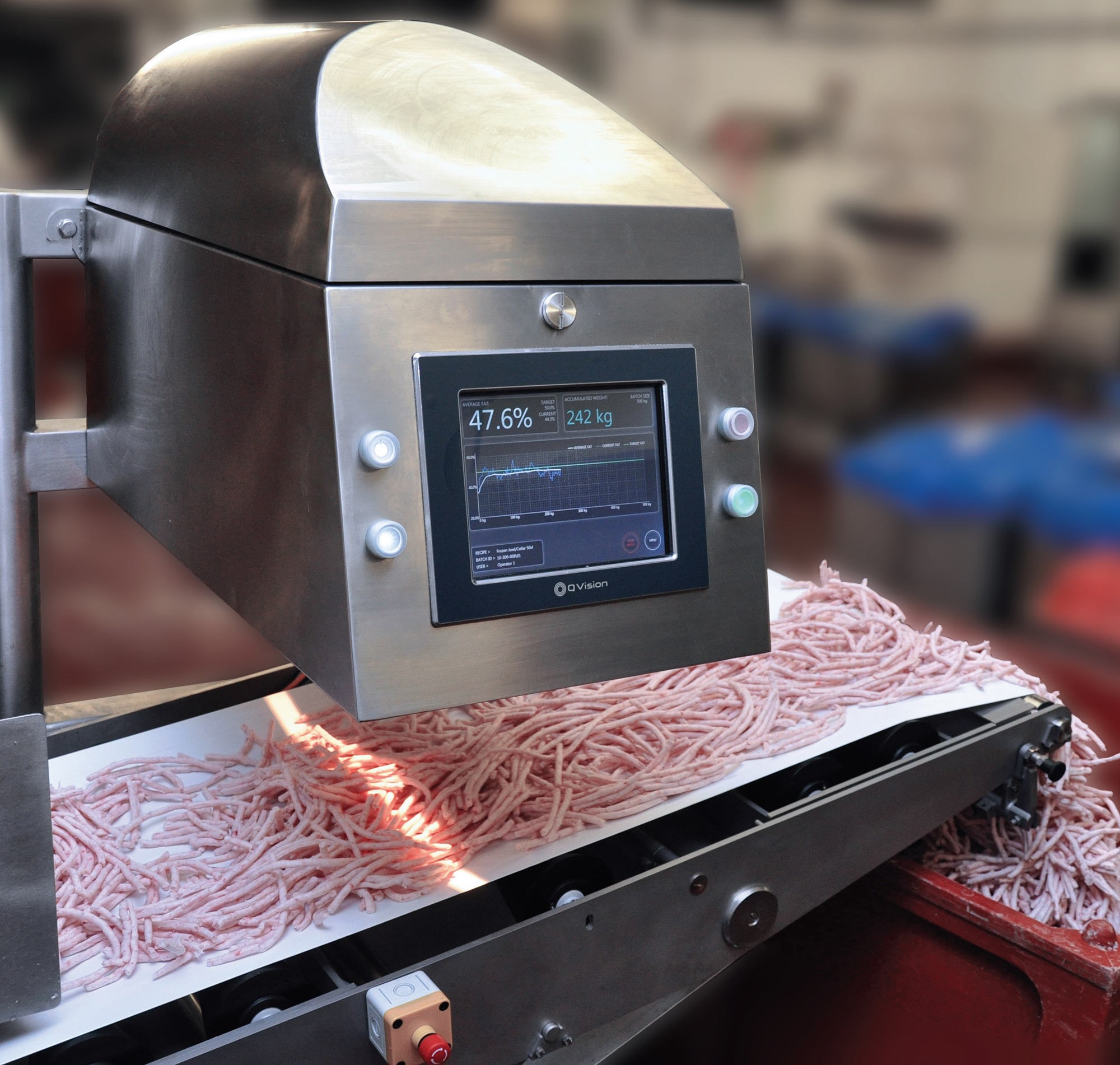

The four components are supplied separately in dolavs. They are identified by barcode labels, containing information about weight and estimated fat percentage. Four Marel ColumnLoaders lift the dolavs with base material to release their contents into the silos of four Marel BufferScrews. Once the operator has entered the recipe for the batch on the display terminal, the BufferScrew’s integrated weighing device determines the dosage. The raw material is transported, in quantities controlled by the recipe, from the BufferScrews to the FATscan. FATscan is the only method on the market for fat measurement on chicken carcasses. It analyzes and calculates the fat percentage of the incoming material, controlling the process in real-time. The FATScan accurately measures and displays the chemical lean (CL) content, minimizing the giveaway of this valuable component of meat to a minimum.

Quality and consistency

After having been scanned, the carcass products are ready to be mixed, in Marel’s Poultry MSM Line by two Marel SoftMix 400 mixers, each with a capacity of 4,000 liters. The fully automated mixers strictly follow the recipe, containing information about cooling, mixing, etc. The fat percentage is constantly monitored and adjusted in the mix.

When done, the mixers discharge to a conveyor belt. Now a bone separator separates the bone content from any skeletal muscle still attached to the carcass (without changing the fat percentage), creating the MSM meat, every time with the same fat content and high quality.