Information

The linear ProFIVE system is the most versatile and adaptable in its field, for harvesting meat from beef bones. With its advanced linear press technology, with several patents, it produces various meat qualities and provides additional yield at the same time.

Thanks to new technology, the ProFIVE enables processors to maintain consistent meat quality, while harvesting up to 6 % more yield of input weight, compared to existing systems (at a capacity of up to 2,500 kg/hr).

How does it work?

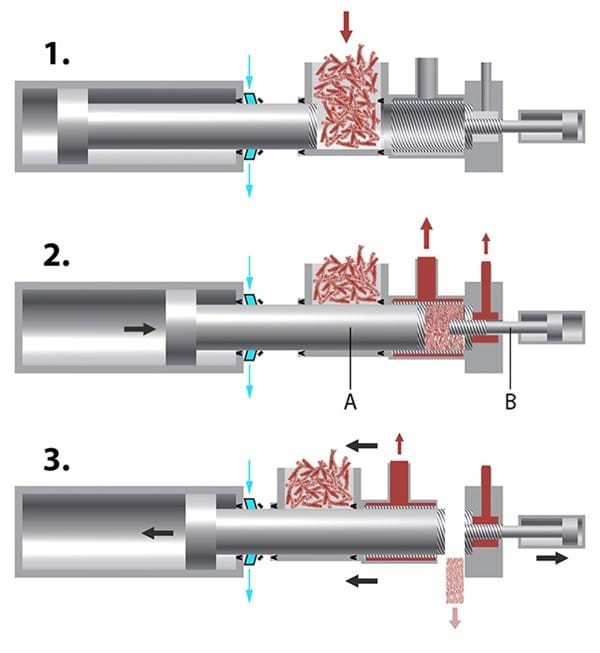

The ProFIVE meat harvester with several patents is suitable for beef bones (neck, loin, e.g.) which are fed into the filling chamber (1).

From there the main ram transports them to the pressing chamber. Gentle pressure causes the bones to rub the meat off one another and allows it to pass through the filter (2).

In the case where high quality 3/5 mm meat is produced, the main plunger (2.A) and counter plunger (2.B) work together in a patented sequence to press the bones more intensively and increase the pressing efficiency.

The bones are retained inside the filter and discharged at the end of the cycle (3). The meat is fed through large diameter pipes into a belt separator to remove sinews, cartilage and the occasional bone particle.

- Payback less than one year

- Unique patented pressure technology

- Infeed capacity of 2.500 kg/hr (5.500 lbs/hr)

- Durable seal on the main ram

The ProFIVE harvests meat at both high quality and high yield and enables processors to produce different meat qualities with the one system – from 3/5 mm minced meat to 1 mm mechanically separated (MSM) meat.

Minced meat is ideal for fresh products like hamburgers, whereas MSM meat is used for cooked products like luncheon meat and hotdogs.

The ProFIVE accepts beef bones, both primal and deboned parts, such as neck bones, loin and chunk bones, brisket (breast bones) and rib bones

The flexibility and adaptability of ProFIVE allows you to produce the perfect raw material for different qualities and quantities of end products. A number of possibilities: Hamburgers, corned beef, bologna sausage, sausage rolls, luncheon meat, salami, fresh sausages

The ProFIVE has been realized with the cosponsoring of the Dutch Ministry of Economic Affairs, the province of Limburg, the province of Noord Brabant and the city region Eindhoven (SRE).