Information

Monitor fillet quality

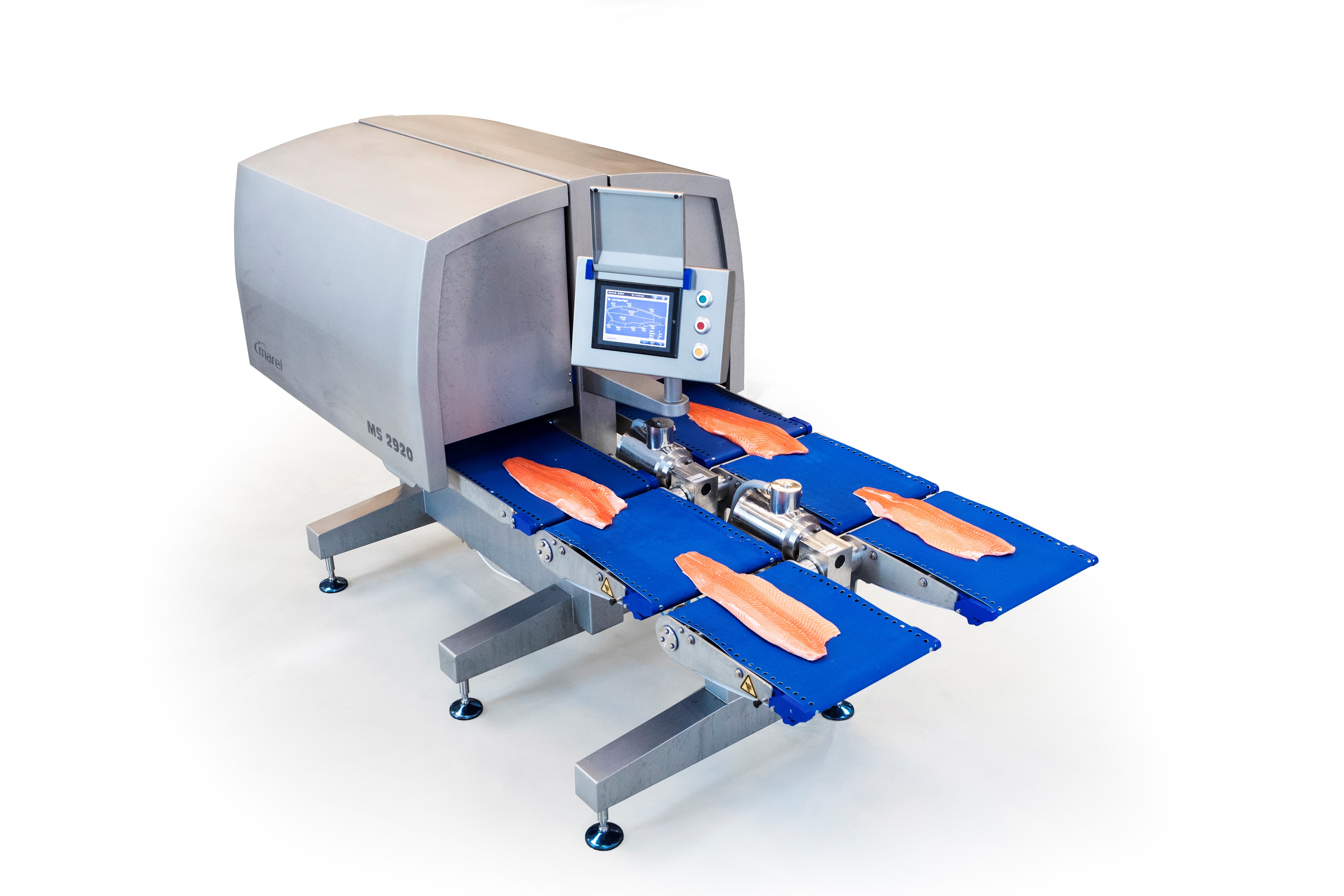

After filleting, the dual-lane QC Scanner can scan each fillet to detect its color, any melanin and blood spots, and any trimming defects such as belly membrane, belly bone or back defects. Fillets are automatically sorted according to preselected tolerance settings. After skinning, the QC Scanner can sort fillets for rework based on the detection of any skin pieces and brown meat.

Vision-laser weighing

The QC Scanner calculates the weight of each fillet using vision laser scanning technology that measures the volume of each fillet. This feature can be used to indicate the yield trend, to determine when adjustments on the filleting machine might be necessary.

Quick and easy operation

All settings are easily made on the scanner’s user-friendly color touchscreen, and programs with different tolerances can be stored so that settings can be changed quickly and easily. The belts are easy to remove for cleaning to help ensure a high level of hygiene.

Real-time monitoring with Innova Food Processing Software

The Innova QC Scanner module can monitor QC Scanners, with real-time monitoring, and reporting on the quality of the fillets after filleting and skinning. Information about the quality of the scanned fillets is collected in real-time and stored in the Innova database, enabling users to analyze, sort the material, quality grade and optimize their quality process.