Information

SOFTmix Vacuum with double shaft mixing system is specifically designed for industrial use. The paddles / wings ensure a quick, gentle and homogeneous mixing process. It is equipped with two pneumatic operated front discharge gates for a fast and complete emptying of liquid products. The mixers are equipped with two pneumatic operated front discharge gates for a quick outlet.

The electric control unit is based on panel view PLC system which gives the operator easy access to choose automatic preset mixing programs or run it manually. As optional extras, Marel offers a wide range of equipment such as CO/N2 injection etc. (Please see list below).

The Marel mixers are specifically designed to meet the strictest hygiene requirements in the industry. Paddles and machine housing are made from heavy duty AISI 304 stainless steel. The surface is smooth, the design fully welded and there are no horizontal surfaces, hidden corners, bolts or nuts.

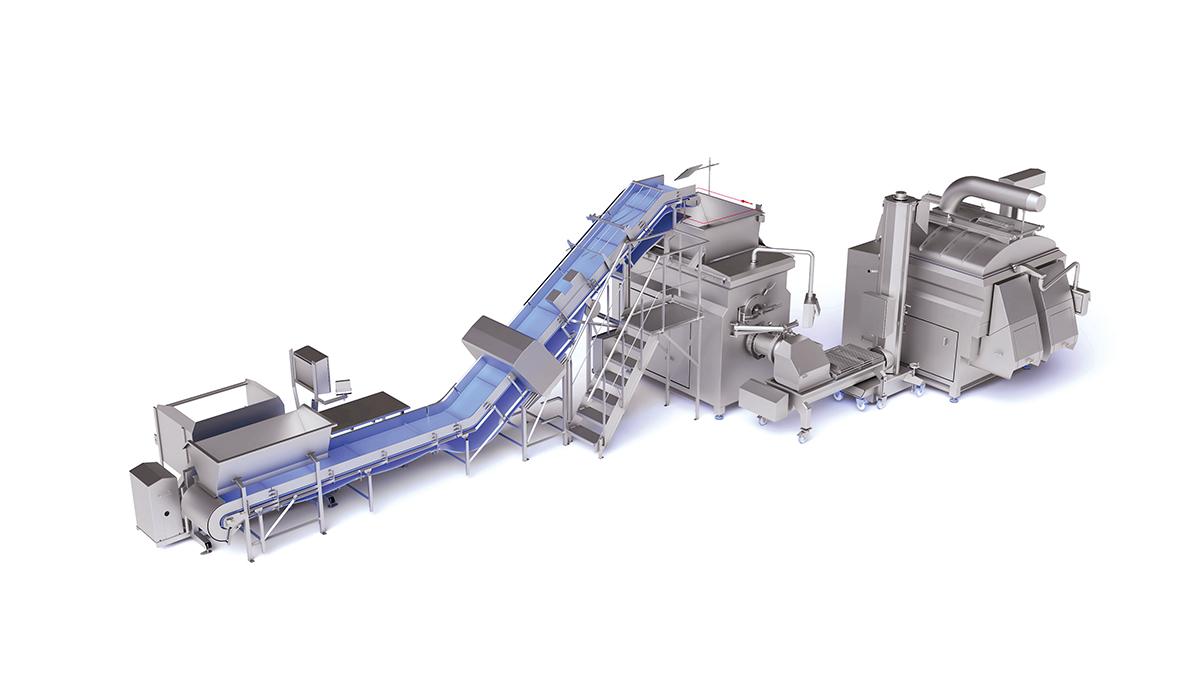

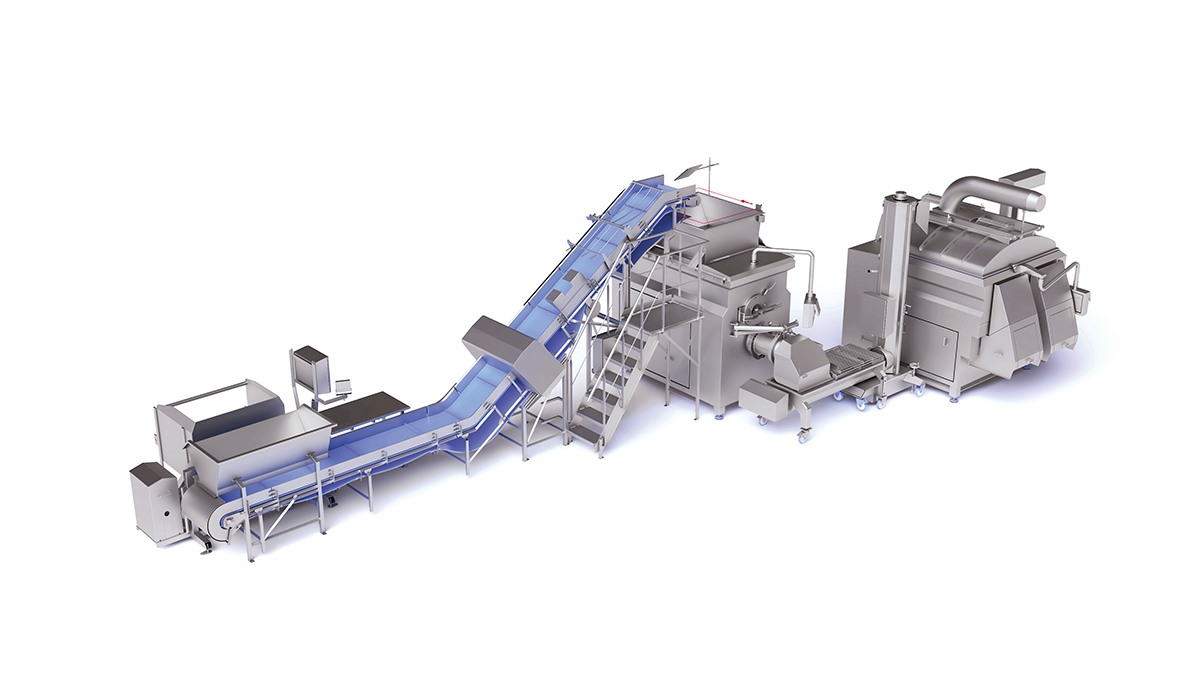

The mixers can be stand alone machines or be part of an integrated processing line.