Information

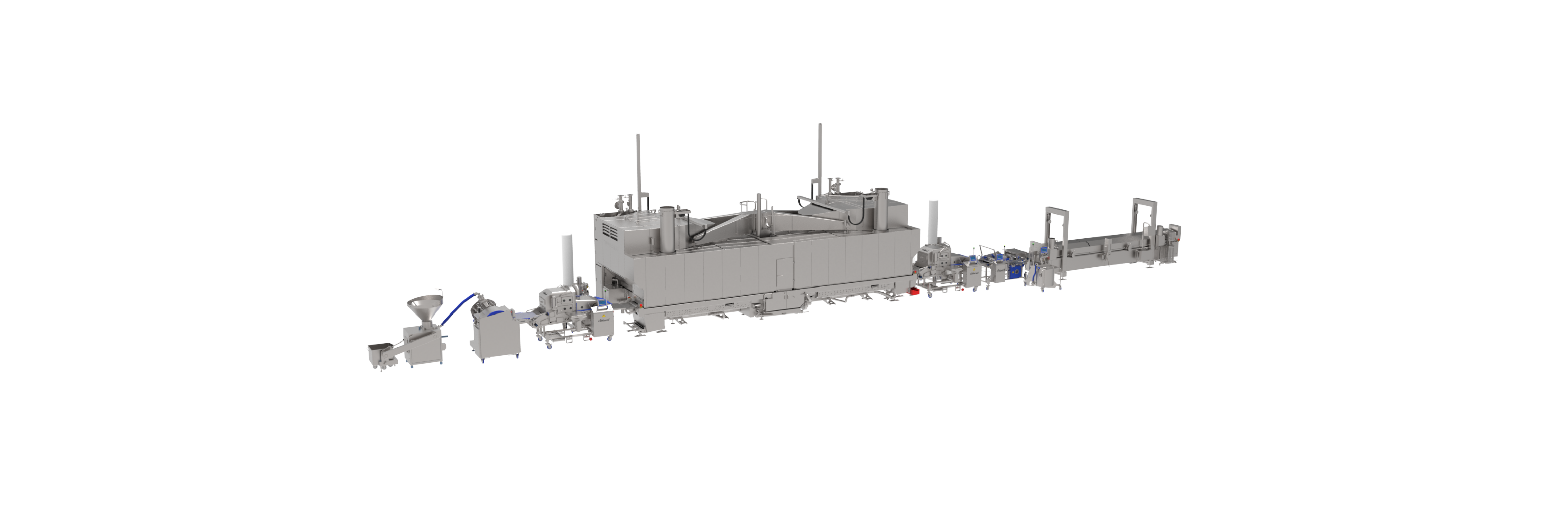

Crispy on the outside and succulent on the inside, tempura chicken nuggets are among the favorite convenience food choices around the world. Marel knows the ins and outs of a consistent and high-quality production of tasty, golden-colored nuggets.

The starting point for the Tempura Nugget Line is the meat mass preparation. Chicken meat and functional ingredients are processed to a workable meat mass, which is chilled. This is done to create the proper viscosity, needed for forming the nugget shape in the RevoPortioner

Innovative coating process

The coating process begins as usual, by pre-dusting the nuggets in by the Active Flour Applicator to increase pick-up in upcoming coating processes. The flour absorbs water, creating a fluffy layer around the nugget. The nuggets now go through a heat treatment process. In the oven, a steam environment is created, which ensures that the nuggets cook steadily and quickly to a safe temperature. The steam also benefits the quality of coating.

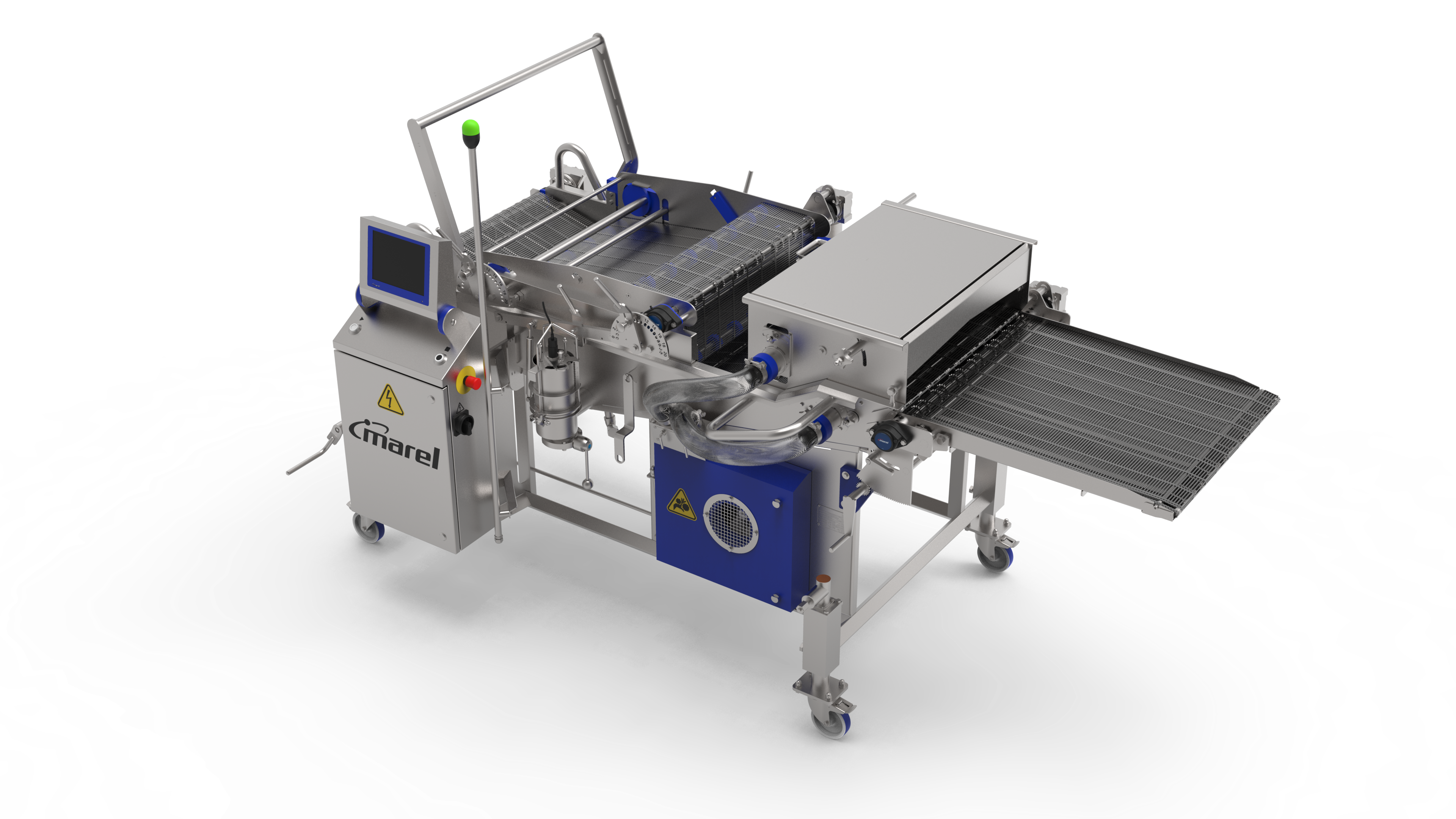

Now the nuggets are ready to run through the final coating process. A second Active Flour Applicator applies another layer of flour to create an adhesive layer between the product from the oven and the wet tempura. The dry coated nuggets enter the Active Tempura Applicator where they are dipped into tempura (a thick batter with leavening agents, producing CO2 when fried), acquiring their typical appearance. Excess tempura is removed leaving just the right amount of coating.

Restaurants and supermarkets

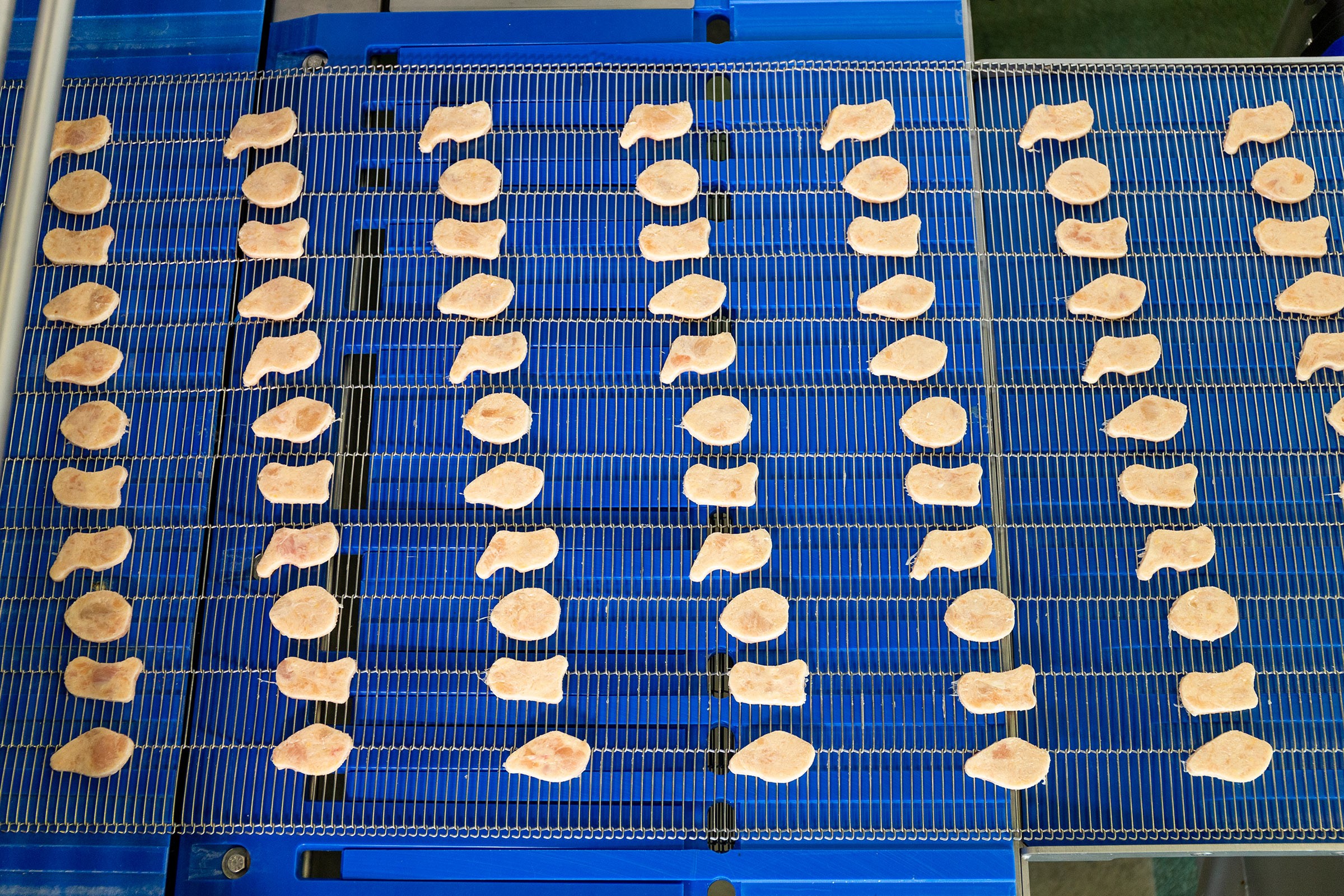

As the nuggets are freshly coated and already fully cooked, they're ready to be par-fried in the GoldFryer. Immersion in frying oil is for fixating the tempura layer only. Here, teflon strips prevent nuggets from sticking to the conveyor belt.

Finally, the tempura nuggets are frozen and packed, to be sold in restaurants or supermarkets. The final frying is done just before eating at home or in a QSR restaurant.