Information

Filleted leg products are gaining popularity worldwide. More and more people consider it a waste to just debone the breast and downgrade the other parts of a chicken.

Carcass balance – making optimal use of every part of the broiler – means a big opportunity for poultry processors to add maximum value to legs and obtain a better price for such upgraded products.

When in-line filleting is not an option, Total Leg Deboning is also available as a stand-alone solution with manual shackling of off-line legs.

Flexibility to debone

As a poultry processor with a sharp eye for incoming orders, you’ll have full flexibility to opt for total leg deboning or not. At any time of day, you can decide to engage or disengage the inline Thigh Fillet System and Drumstick Deboning System in the cut-up line. When engaged, the total leg will be deboned automatically at high speed with inline harvesting of all leg meat. At no point in the process, there's a need for manual trimming.

Thigh filleting

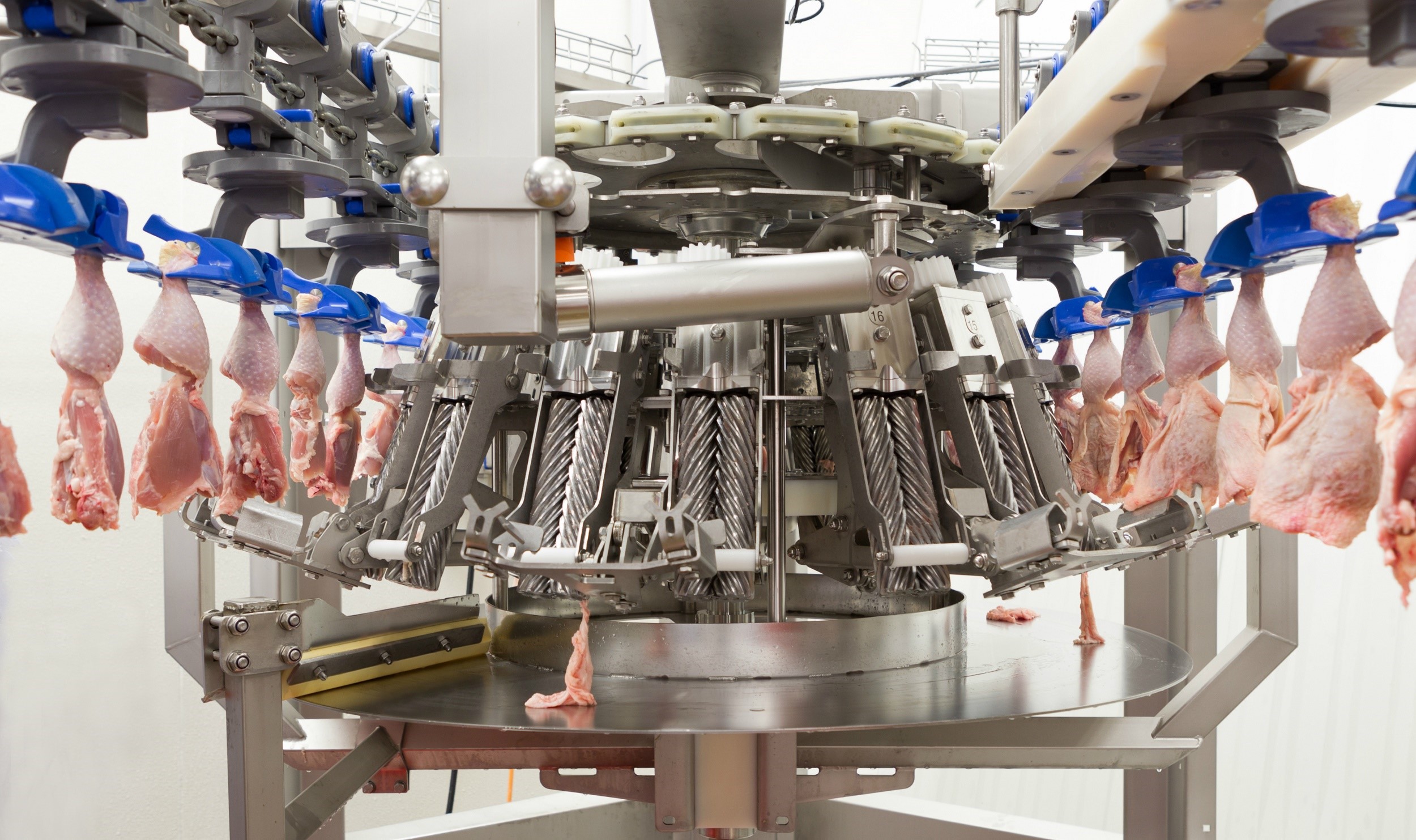

Staying inline in the ACM-NT cut-up line, legs are forwarded to the carousels of the Thigh Fillet System. The bone is separated from the meat with utmost efficiency and consistency, simulating a skilled “butcher’s cut”. The result is a retail quality thigh fillet.

Drumstick deboning

Once thigh meat has been harvested, (a selection of) the remaining drumsticks can be deboned. The high-speed inline Drumstick Deboning System carefully separates the meat from the bone. This gives the drum meat more value than its bone-in form, being a tasty base material for ready-made products.

- Add maximum value to leg meat

- Upgraded products benefit carcass balance

- The world's first fully inline, high capacity total leg deboning solution

- Thigh filleting and drumstick deboning work closely together

- State-of-the-art techniques carefully separate the meat from the bone

- Easily engage and disengage the deboning systems

- No need for manual trimming

- Deboned leg meat to be sold as fresh meat or convenience products

- Also available as stand-alone solution