Information

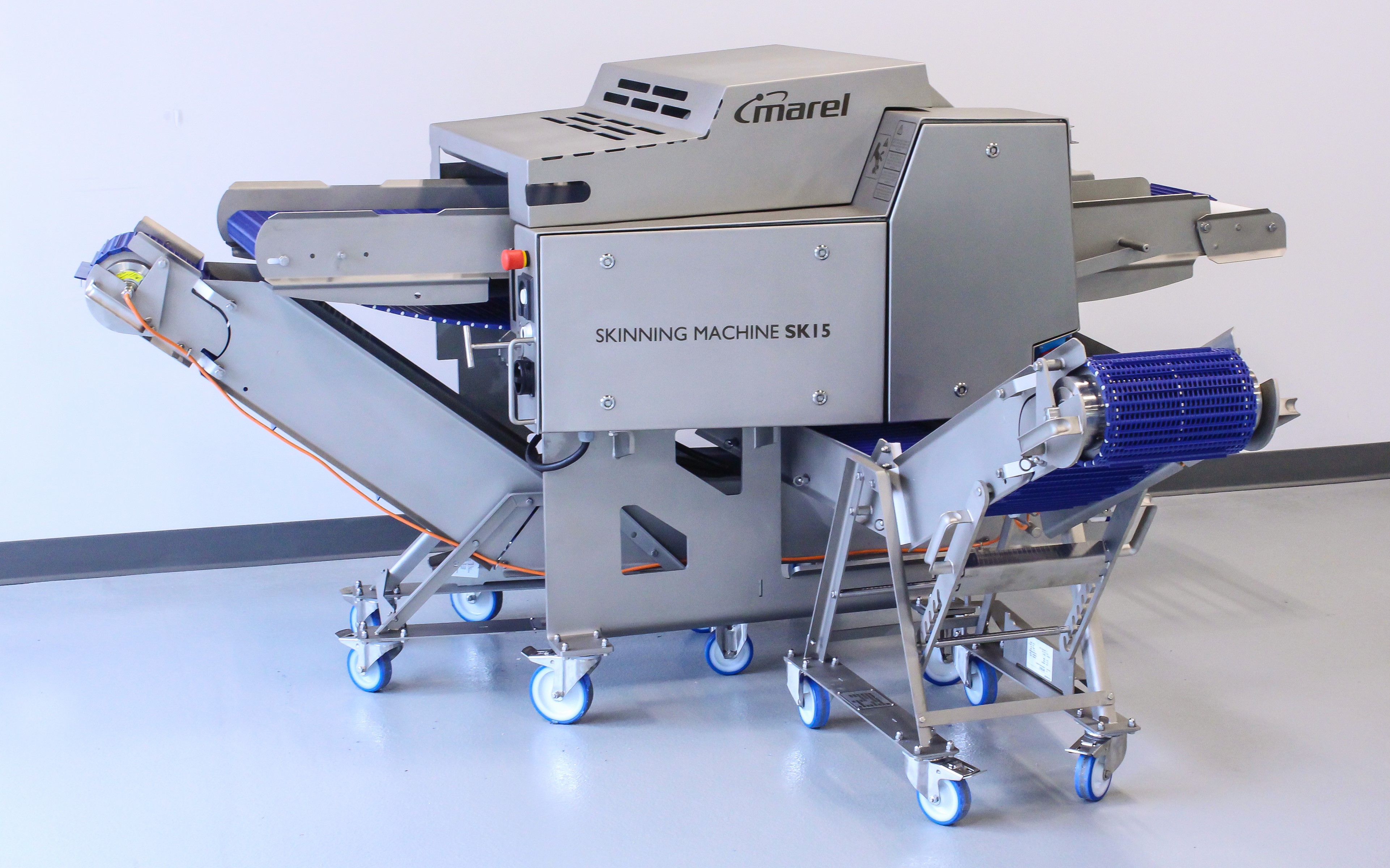

The conveyorized AutoReturn derinding skinner Townsend SK 15-330 can be used in heavy applications to remove the skins and/or heavy membranes from flat meat that needs to be skinned on both sides. An innovative feed-back and takeaway conveyor system allows skinned product to be returned to the operator and reintroduced to the skinning mechanism along with trimmings taken away from the machine.

Features

- Available in 20" (505mm) skinning width

- "Line bored" cabinet creates a perfect alignment between tooth roll and skinning mechanism

- Shoe can remain on the machine during sanitation to prevent damage

- Single drive belt located on one side for easier maintenance

- Adjustable height exit conveyor is ideal for a multitude of production line layouts

- Hood assist to aid in opening and closing of the hood

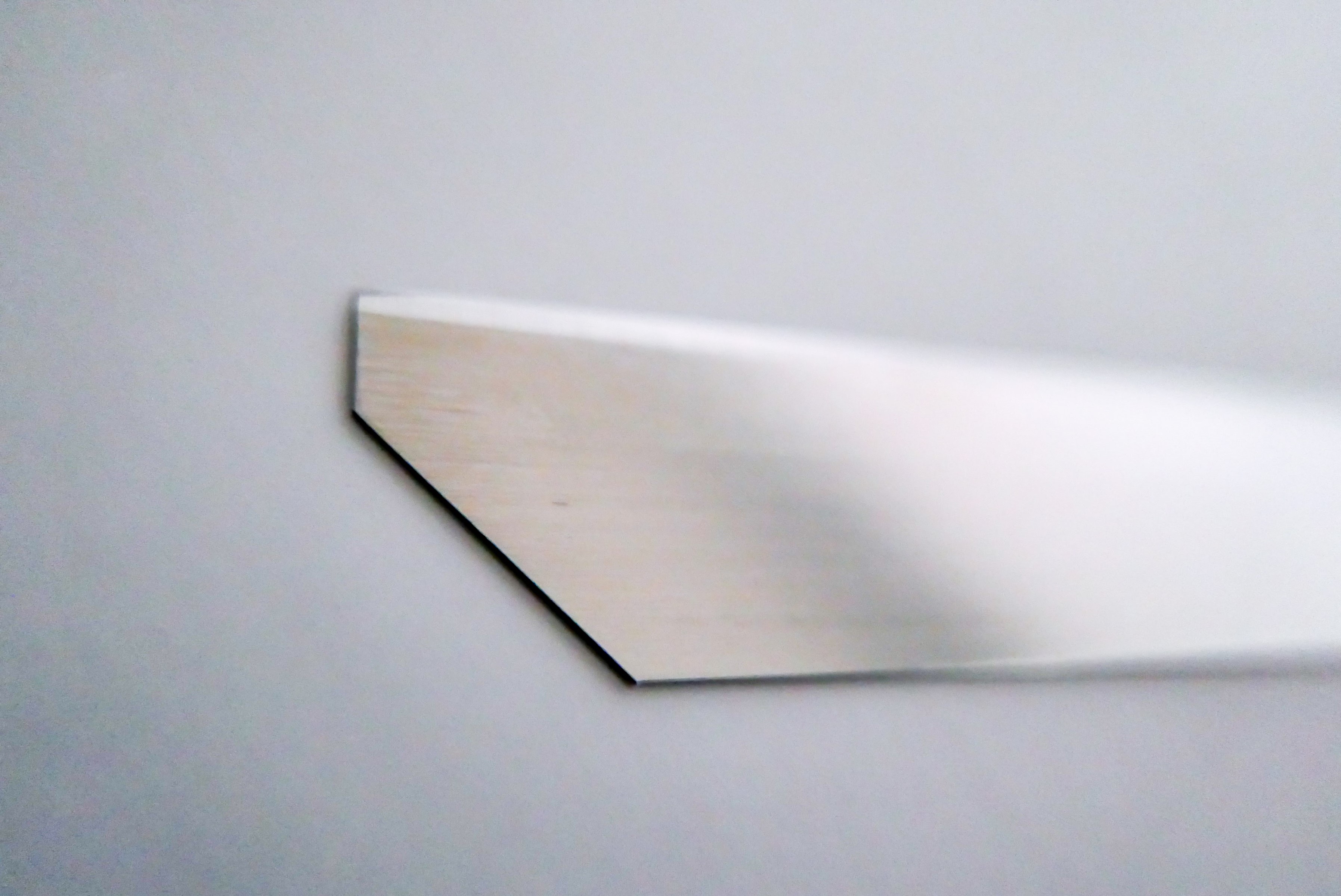

- Available in adjustable and fix blade clamp options

- ThinAdjust control allows for skinning thickness to be adjusted while the machine is running

- Available with return and takeaway conveyor extensions to allow for a multitude of production line layouts

- Open conveyor frames for easy maintenance and sanitation

- Low cost of ownership

- Easy to adjust air or spring top feed/open bite cylinders allow for optimal performance on many different products

- Easy to lock down top feed mechanisms