Information

For the transportation of pork carcasses or carcass parts, various technologies are applied according to the products to be transported and/or the purpose. The transportation technologies can be divided into the following groups.

Hanging conveyor systems

For efficient and reliable transport, we have developed various transport conveyor systems.

The conveyors have a basic concept consisting of a double-guide profile, which is integrated into the underlying transport path. Each conveyor has a separate drive unit and a unit that automatically maintains the correct tension of the conveyor chain.

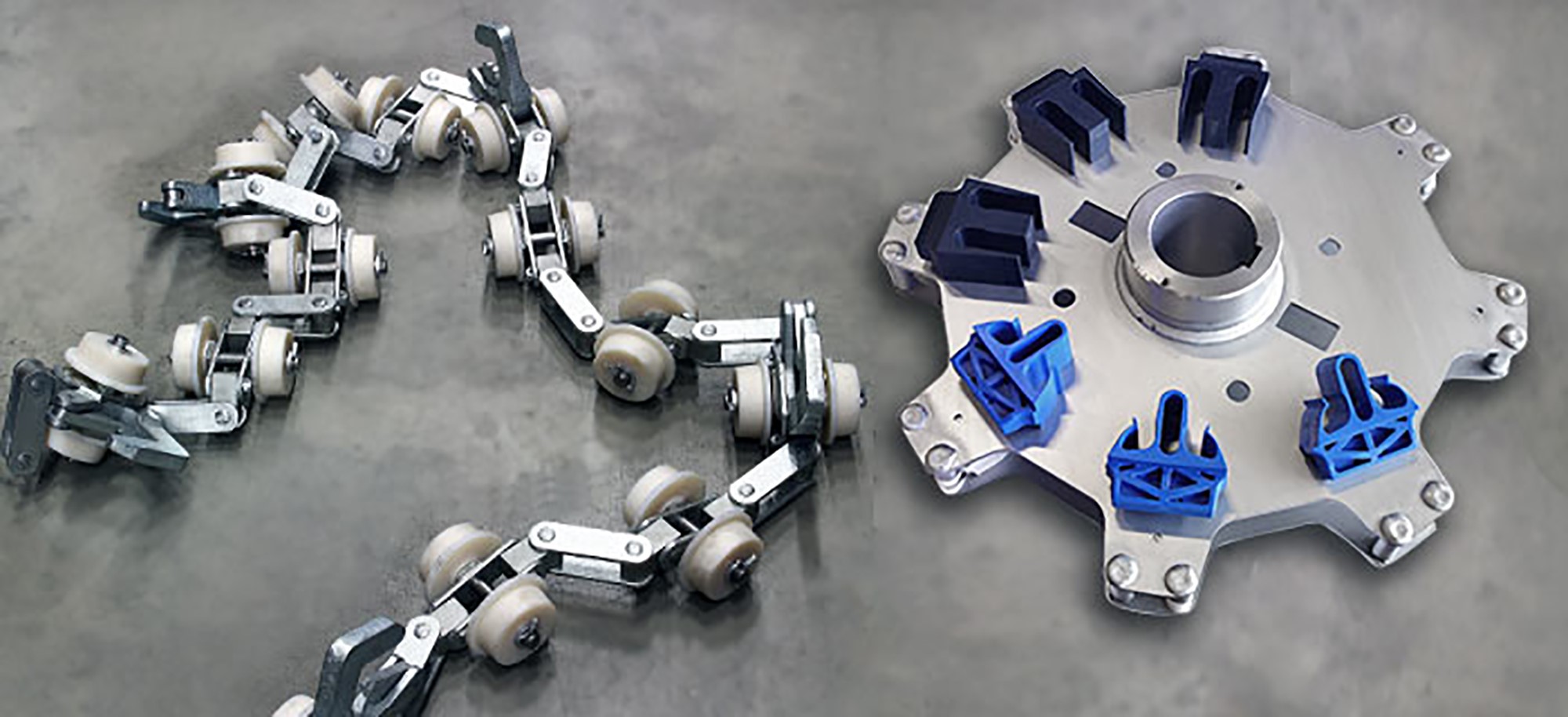

The application of multiple pulleys makes any conveyor route possible. The pulleys used in conveyors have been designed by Marel and the specific tooth shapes ensure a long life for each chain.

The chains used have a modular design and can be built according to the specifications of the customer. The chains can also be supplied in low-maintenance or maintenance-free versions. This minimizes the need to lubricate the conveyor system.

The underlying transport path of the conveyor can be supplied tailored to customer requirements, including the conveyor rail, the double rail conveyor and the flat rail conveyor as the standard options. There are also systems available that use the conveyor chain simultaneously to carry the carcass or product.

Storage systems

In addition to the transport conveyors, we offer conveyor systems specifically for the automatic storage of carcasses or products in a cold store. The degree of automation in the cooling rooms depends on specific requirements.

Where transport conveyors often run continuously, the storage systems are characterized by a discontinuous operation where the carcasses always move forward a certain distance.

The transport conveyor systems and storage systems can function very well in a fully automated cooling room.

Rail return systems

After the carcasses are transported from a slaughter hall to a cold store, cutting room or dispatch, the dressing hooks must be cleaned and returned to the slaughter hall. To this end, we supply tailored return systems that are characterized by a compact and flexible design.

The return system can also serve as a storage system. The return system consists of multiple separate conveyors, which each have their independent drive. Should this be desired, the return system can be expanded with an automatic hook cleaning system. The return system has its own operating system that can be used in combination with an operating system of a slaughter line.

Push conveyor systems

In addition to the transport conveyors, we offer push conveyor systems for the storage of carcasses or products in a cold store. The underlying transport path of the push conveyor can be supplied tailored to the customer's requirements, including the conveyor rail, double rail conveyor and the flat rail conveyor as the standard options.