Information

Marel PMJ's Wax Reclaim System filters the used wax by removing feathers, fat and other small particles. During this process, the wax returns to its original structure and characteristics without overheating. This fully automatic recycling loop is minimizing the wax consumption per product, improving wax quality, reducing waste and eliminating manual labor completely.

The Wax Reclaim System separates the majority of feathers and down from the used wax. The solid wax coming from the Wax Removers is reconditioned and filtered in this system. The unique filtering system does not require any cooking or high pressure, preventing the wax from spoiling due to feather fat or marrow. After the recycling procedure, the high wax quality is guaranteed.

Wax press

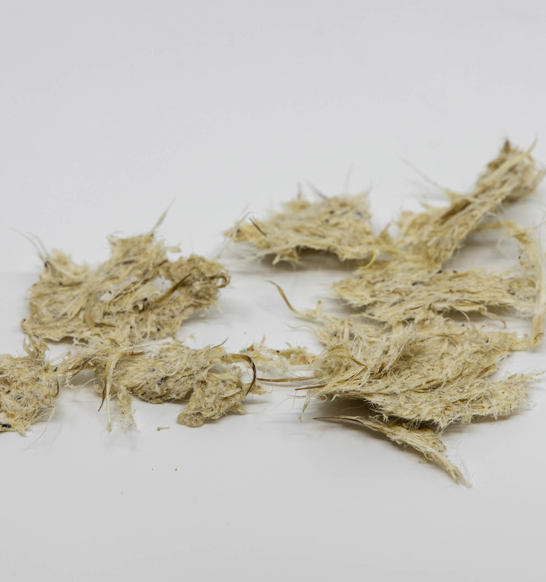

The wax press is an additional feature of the wax reclaim tank and forms the second stage of the recycling process. The feathers and down filtered out by the wax reclaim tank are pressed, in order to remove all remaining wax. This significantly improves the wax reclaim result and increases the volume of reusable wax. Thanks to the specially developed filter screen and pressing device, the wax is freed from feathers, leaving the fat on the feathers.

- Mounted on the wax reclaim tank

- Quick removal system of the filter screen for easy cleaning

Settling tank

The settling tank receives the separated wax from the reclaim tank and wax press. The special design of the tank facilitates the settling of any small particles and duck fat, this residue will stay behind in the tank. The final step includes cooling down the wax to an optimal wax dipping temperature. The wax returning to the dipping tanks is clean and ready to use with its original strength for an optimum result.