Information

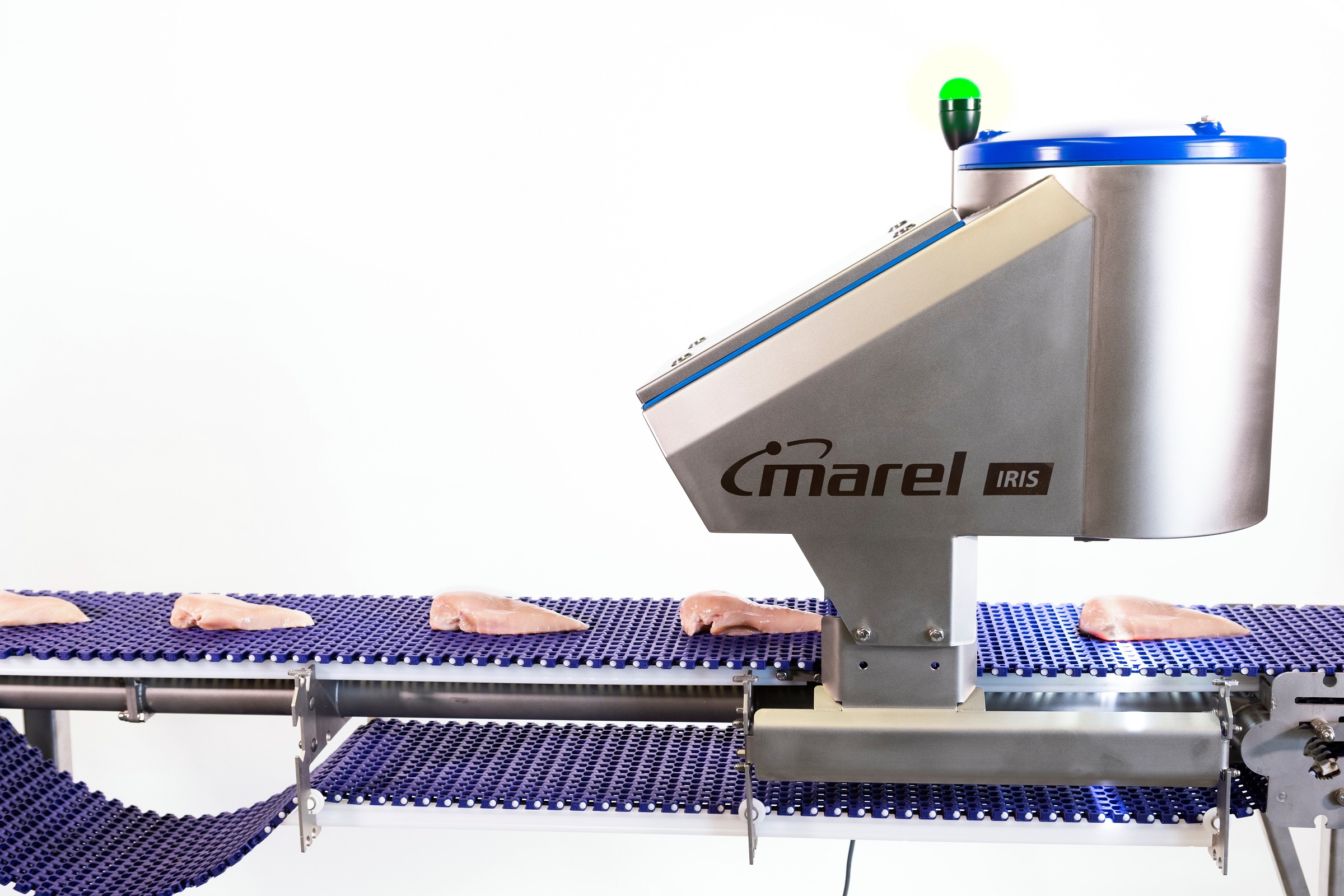

Besides assessing whole products and all anatomic parts, IRIS, the Intelligent Reporting, Inspection & Selection system, can assess breast fillets. IRIS FI (Fillet Inspection) is an advanced camera system developed for this task.

Quality assessment on a belt

If you want to have continuous and objective quality inspection of each individual breast fillet on a belt conveyor, Marel’s IRIS FI camera system for inspection after trimming is a big help. By detecting visual quality characteristics, camera inspection after the trimming station allows for in-line quality control of the fillet without any manual hassle. It gives you full real-time information and reporting on the quality of the product which is about to enter the portioning, convenience food production or packing process.

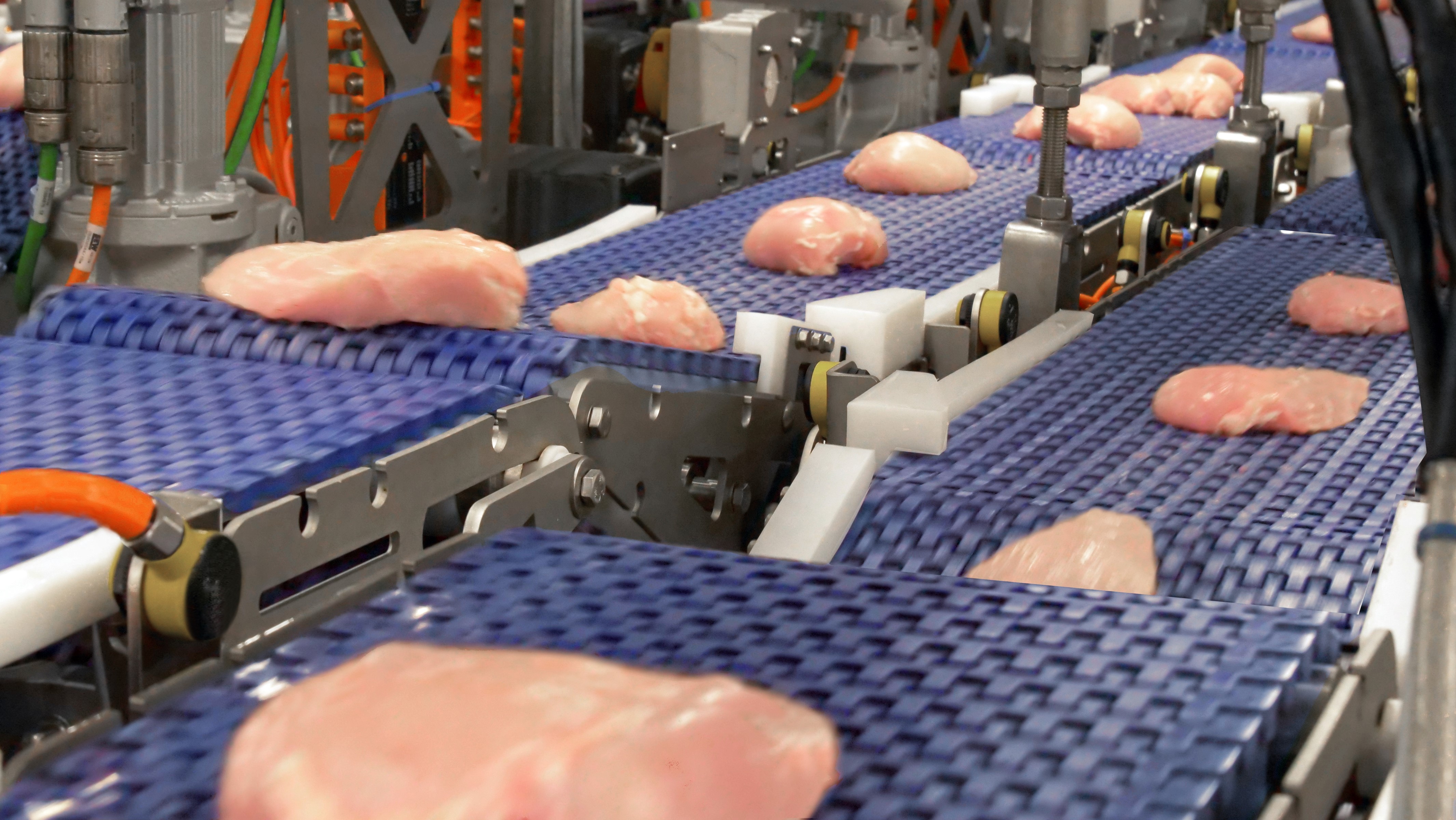

Best destination

When you demand the very best utilization of every single breast fillet, you want to distribute the fillets to the best matching destinations, based on quality data. IRIS FI is a vision grading system that, combined with Innova PDS, allows you to process the quality data in real-time and get maximum value out of each fillet. IRIS FI adds visual quality to the fillet’s dataset, which already includes individual fillet weight data. By linking all data to production orders, IRIS FI contributes largely to the determination of the fillet’s destination.

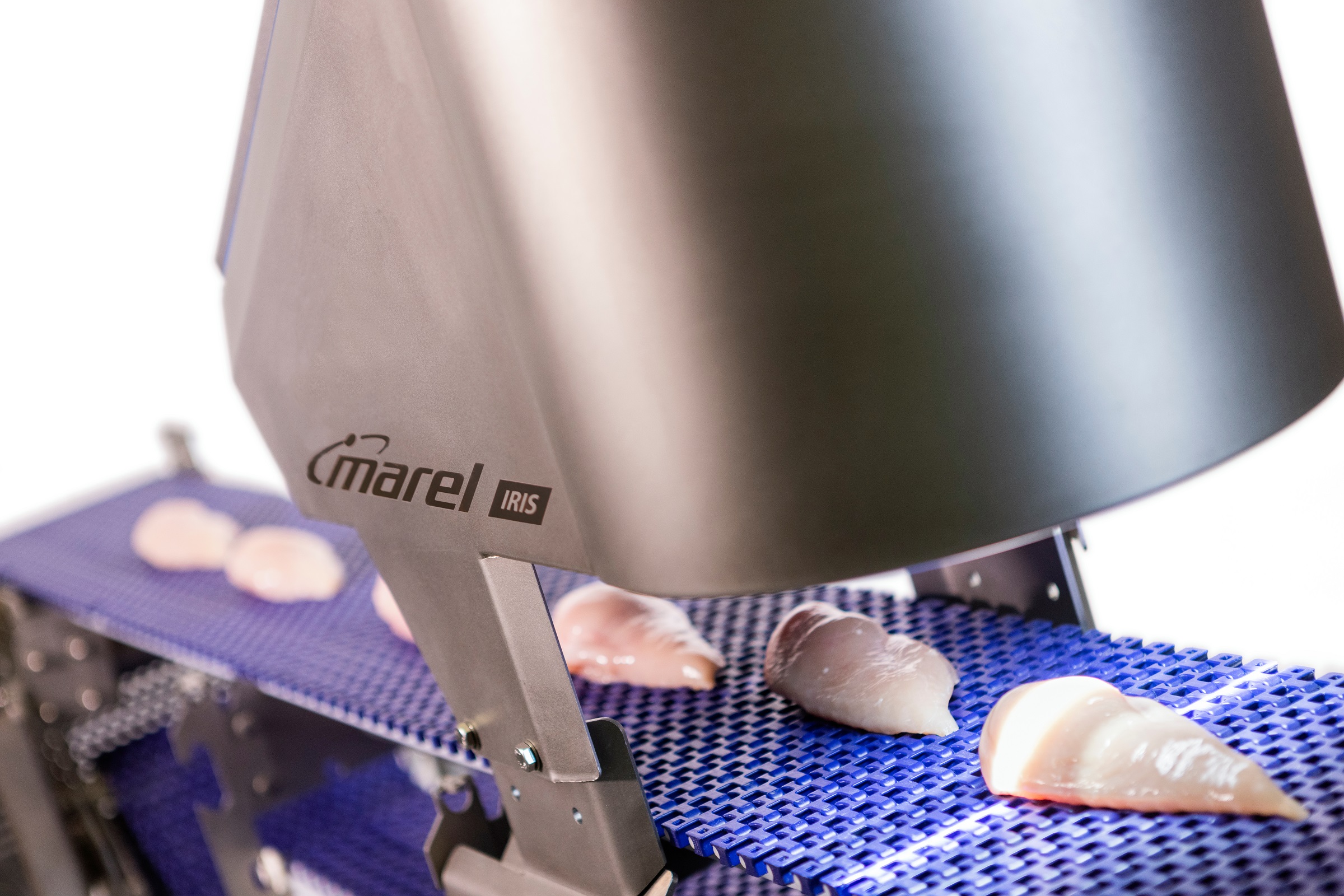

IRIS FI can detect visual anomalies or defects such as blood spots, skin left on and color deviations.

Traceability

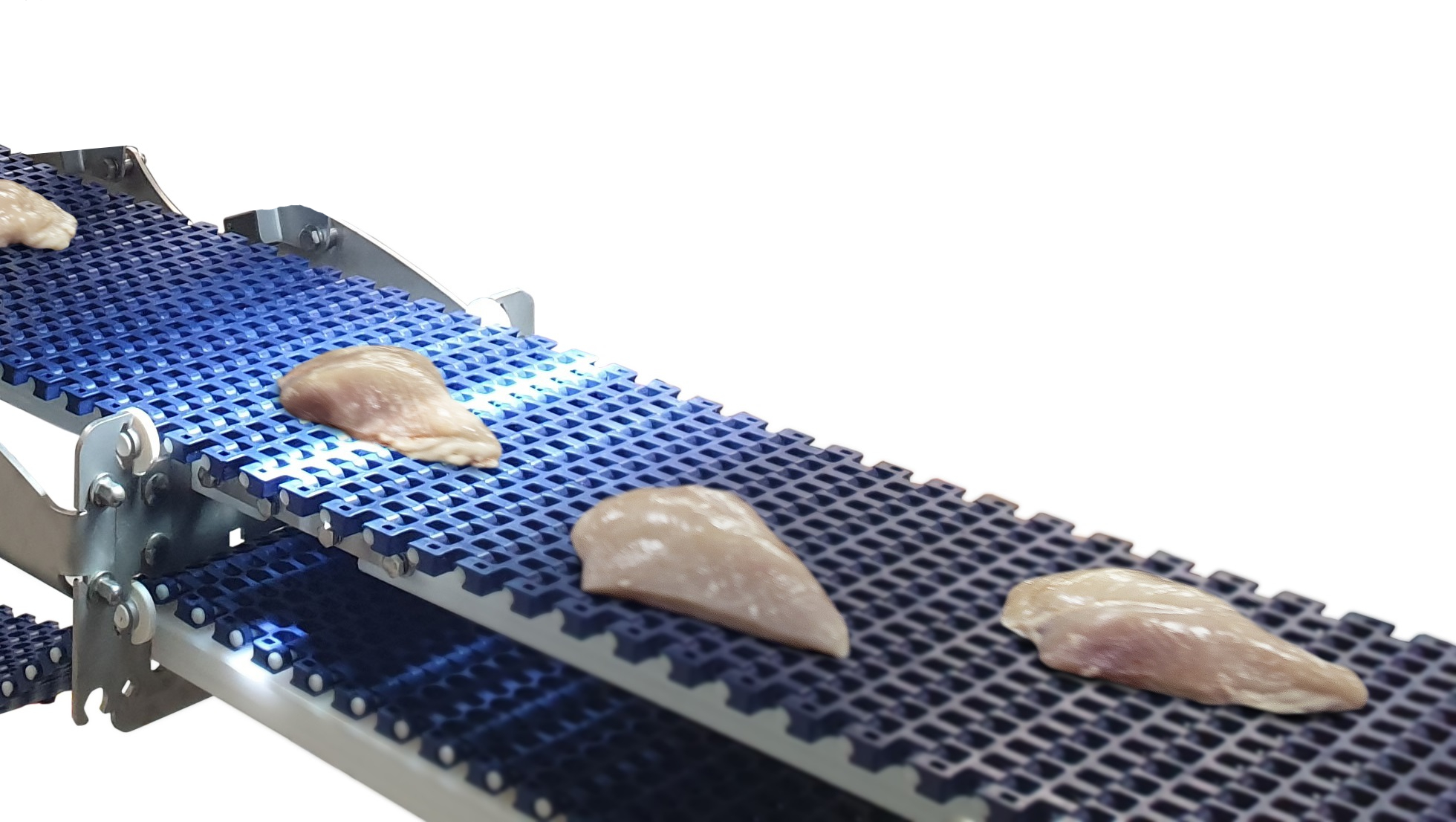

Until now, traceability of products was only possible as long as they were shackled in an overhead conveyor. After release on a conveyor belt, traceability was lost. Combined with state-of-the-art software and SystemFlex conveyor intelligence, Marel’s IRIS FI is able to maintain traceability of products on the conveyor belt.

No human bias, but objective facts

There is no need for manual touching or subjective human judgment, enhancing hygiene, product integrity and food safety, while saving labor. All products, even if they are spread randomly over the belt, are inspected automatically and accurately. Quality-dependent decisions aren't based anymore on estimates but on facts, and every product will exactly be put into its most profitable form.