Information

Low-pressure forming

Whether you are forming burgers, nuggets or fish cakes, the RevoPortioner will ensure you have end products of the highest quality. Low pressure ensures that the texture and structure of the raw material are retained and that every product has a uniform shape and accurate weight.

Endless product possibilities

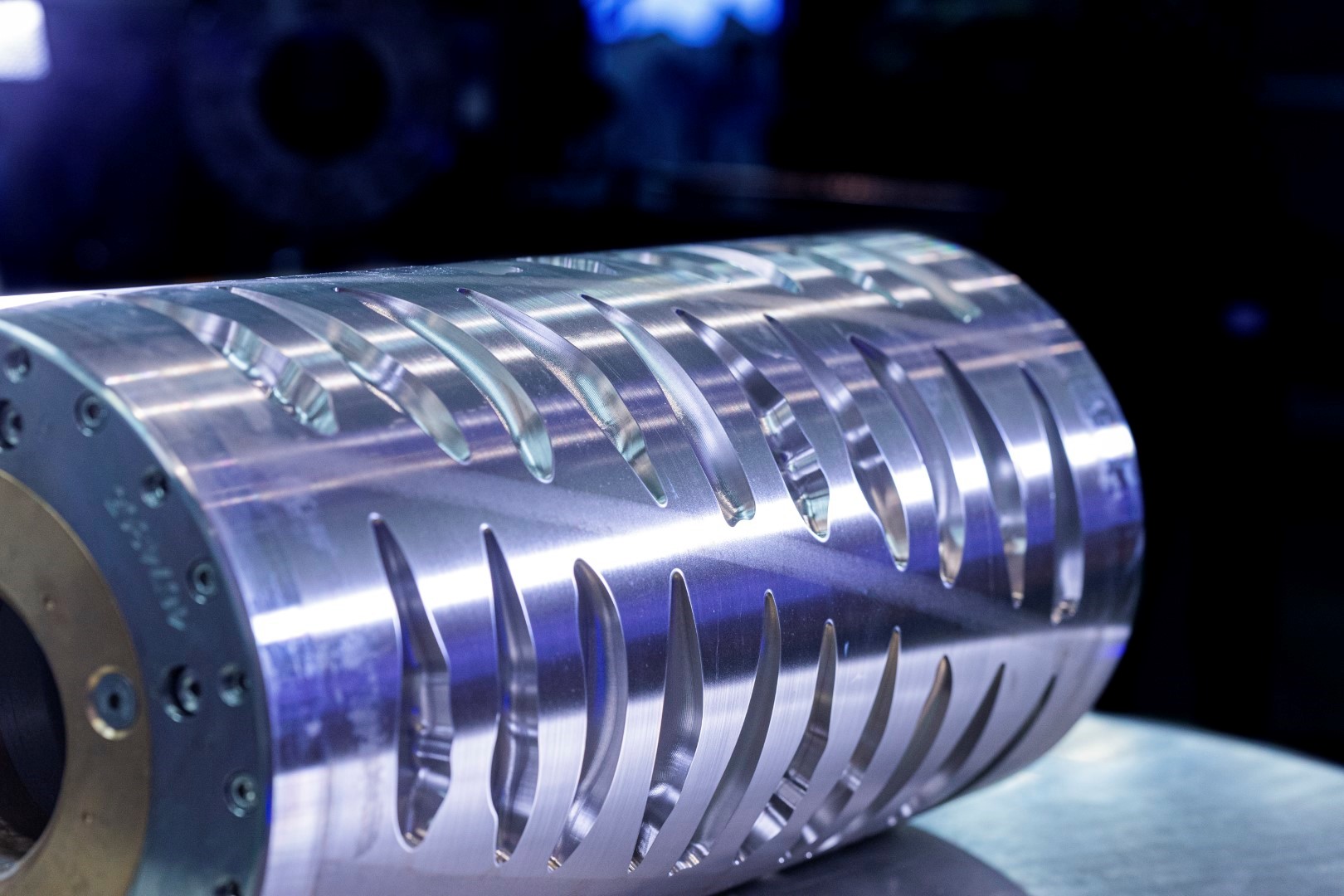

Regardless of whether your raw material is whole muscle or emulsion mass, interchangeable forming drums can create practically any 2D or 3D product shape you desire. They are quick and easy to change, giving a highly flexible production process.

Increased capacity and quality

Forming drums are available with innovative Helix Drum technology to increase production capacity. They also ensure a more controlled filling pressure with a more constant flow of raw material, which further improves product quality.

Air release – no water

Air instead of pushers and water releases products, eliminating smearing and resulting in a much higher quality finish. It also has huge benefits for downstream processes such as flouring, battering and breading and guarantees you a clean working environment.

A RevoPortioner for any capacity

Every day, convenience food processors worldwide benefit from the innovative forming solutions we’ve been developing for more than 25 years. With the introduction of the RevoPortioner 1000, there’s now a RevoPortioner to fit any food processing production line, from the smallest family-owned business to the largest processors supplying the world’s leading QSR chains.

Download our eBook to discover more about the technology behind the RevoPortioner.