Information

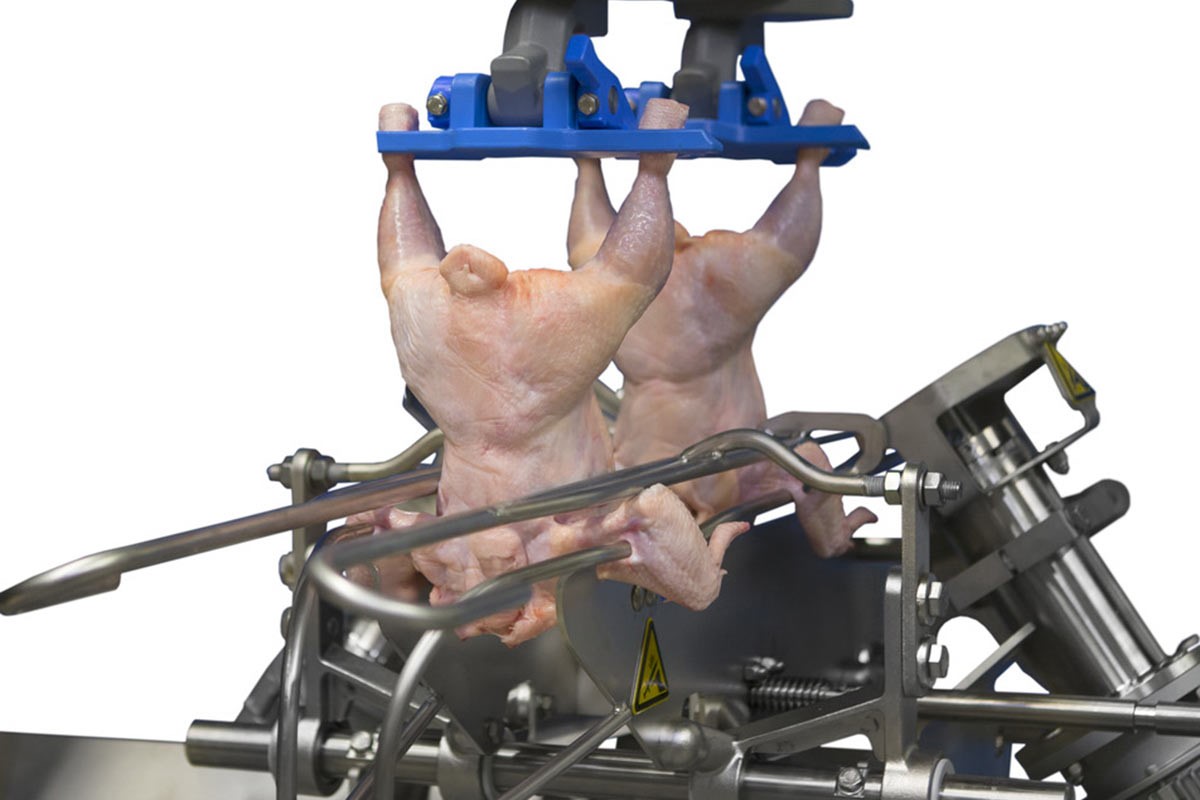

The ideal mid-wing cut should achieve perfect skin coverage without compromising the skin integrity of the adjacent drumette piece. At the same time, the cut should be fully anatomic, not splitting any bone.

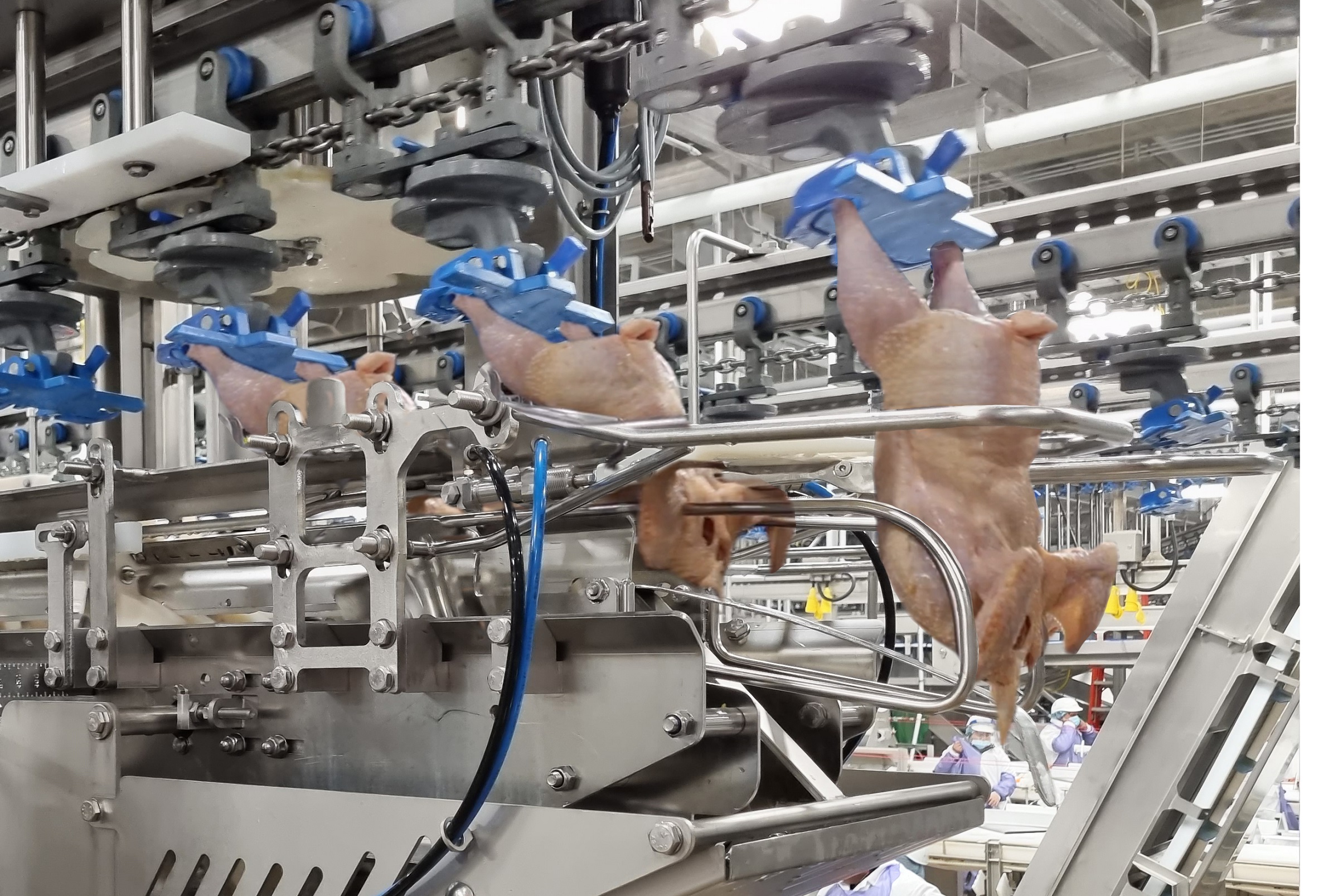

Taking into account the growing customer demand, as well as scarcity in skilled workers, and increasing food safety concerns, manual cutting won’t suffice anymore. Automation is the only answer to process large quantities of mid-wing pieces.

The WingMaster second joint wing cutter, as a module in the ACM cut-up system, succeeds brilliantly in mechanically reproducing the skilled movements of a manual cut. The result is a precisely, anatomically cut mid-wing with an excellent presentation, and with higher yield for the poultry processor.

Q-Wing

The WingMaster processes the left and right wings of one product completely independently. The module can handle wings with or without wing tips. It can also be bypassed without the need for shackle turning. Its automated cutting actions in the ACM line don’t need any staff and require less labor for sorting and rework. This makes the WingMaster also ideal for application in the Q-Wing set-up.