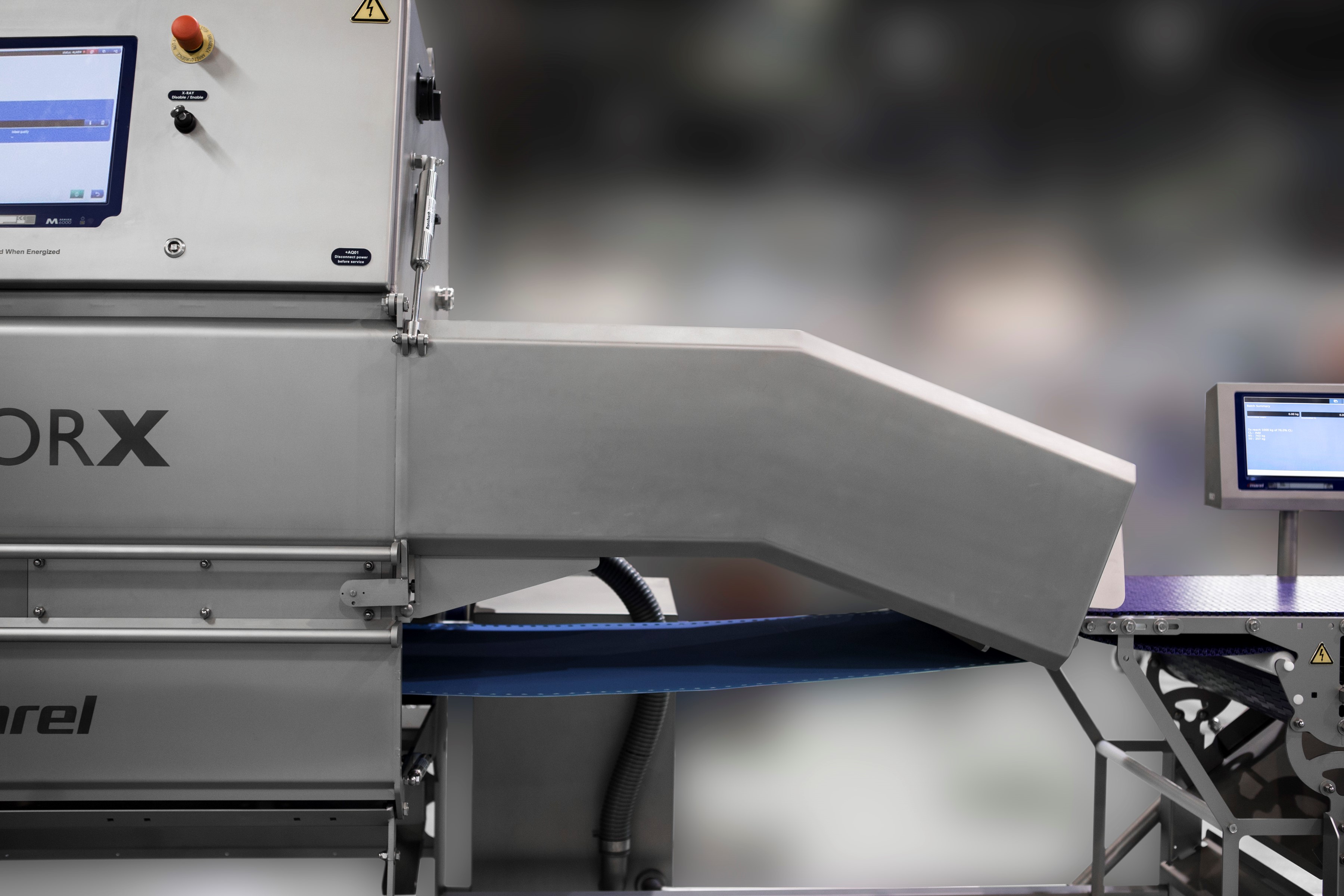

Marel’s new SensorX software creates the perfect balance between highly accurate bone detection and the lowest rate of false positive. With too many false positives, bone performance detection statistics – while looking impressive – will not reflect the true situation and could be misleading for departmental management.

Marel’s latest SensorX software not only reduces the incidence of false positives to an absolute industry minimum but also detects those difficult to find bone fragments more accurately. This means less rework and fewer inspectors, enhancing the machine’s already excellent performance.

Perfect balance

The major advancement in the new SensorX software is that it intelligently combines algorithms with new automatic calibration and a very accurate X-ray sensor, in order to get the most reliable detection. The new software enables the SensorX to create a perfect balance between an increased detection rate and a reduced false positive rate.

However, this balance is a very thin line. When trying to detect the very smallest bone particles, a machine runs the risk of generating erroneous results and jeopardizes its reliability. Therefore, the first aim of Marel was to detect the overall highest percentage of bone particles – big as well as small – in the market. Elaborate testing of the new SensorX software shows that this objective has now become a reality.

When performing bone detection tests, false positives should always be included. If detection results are excellent but the false positive rate is 30%, the machine is useless, because there’s way too much unnecessary rework to be done.