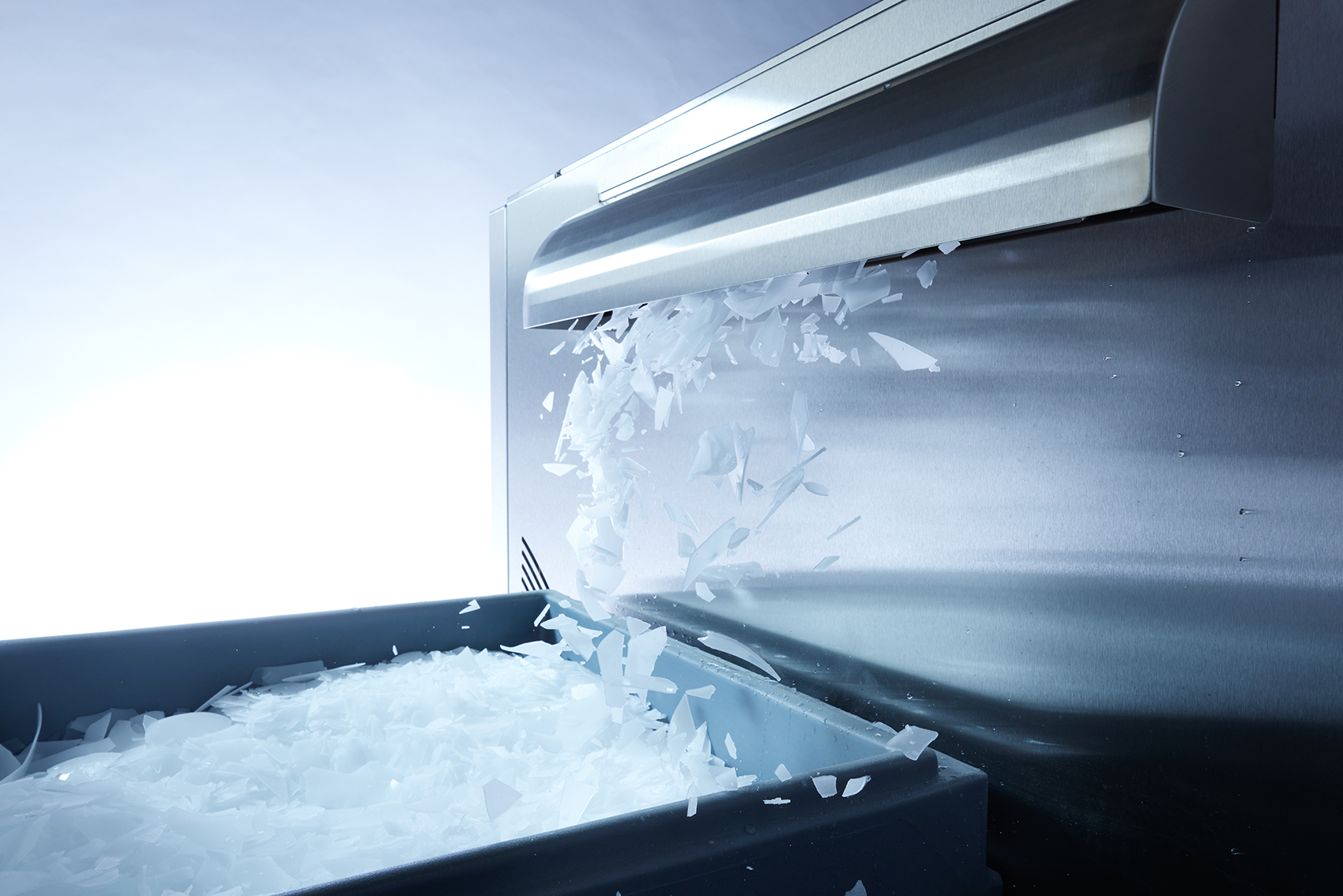

Whether you use ice for rapid cooling, as a key component in your production process or as a way to preserve perishable goods, a MAJA flake ice machine will ensure your ice meets the highest hygiene standards.

We focus on hygiene so you don’t have to

For many years now, we have been investing heavily in developing technology to improve hygiene in ice production. We’ve focused on areas such as ease, automation, digitization and sustainability to create a range of methods and features that ensure you can meet and exceed food safety standards with minimal effort. This is something that really has set us apart from the rest of the market.

Making cleaning as easy as possible

MAJA flake ice machines have been designed in such a way that even the smallest screw is manufactured to meet with strictest hygiene requirements. We also understand how important it is to make the cleaning process as simple and effortless as possible and incorporate this in all design aspects. The innovative tank in our flake ice machines, made entirely from plastic, can be removed for manual cleaning more easily than any other available on the market. Besides that, the evaporator is accessible from all sides and the machine’s water tank is free from integral built-in parts, avoiding hygiene-critical angles and edges and making systematic cleaning easier than ever before.

Automatic sanitizing to reduce time and effort

Even though modern ice machines have a sanitation-friendly design, allowing for quick and easy cleaning, the staff and working hours must still be scheduled to perform cleaning. If the machine is not easily accessible, perhaps in a suspended ceiling or installed on a silo, it can take at least an hours work to gain access, remove, clean and then reassemble components.