Information

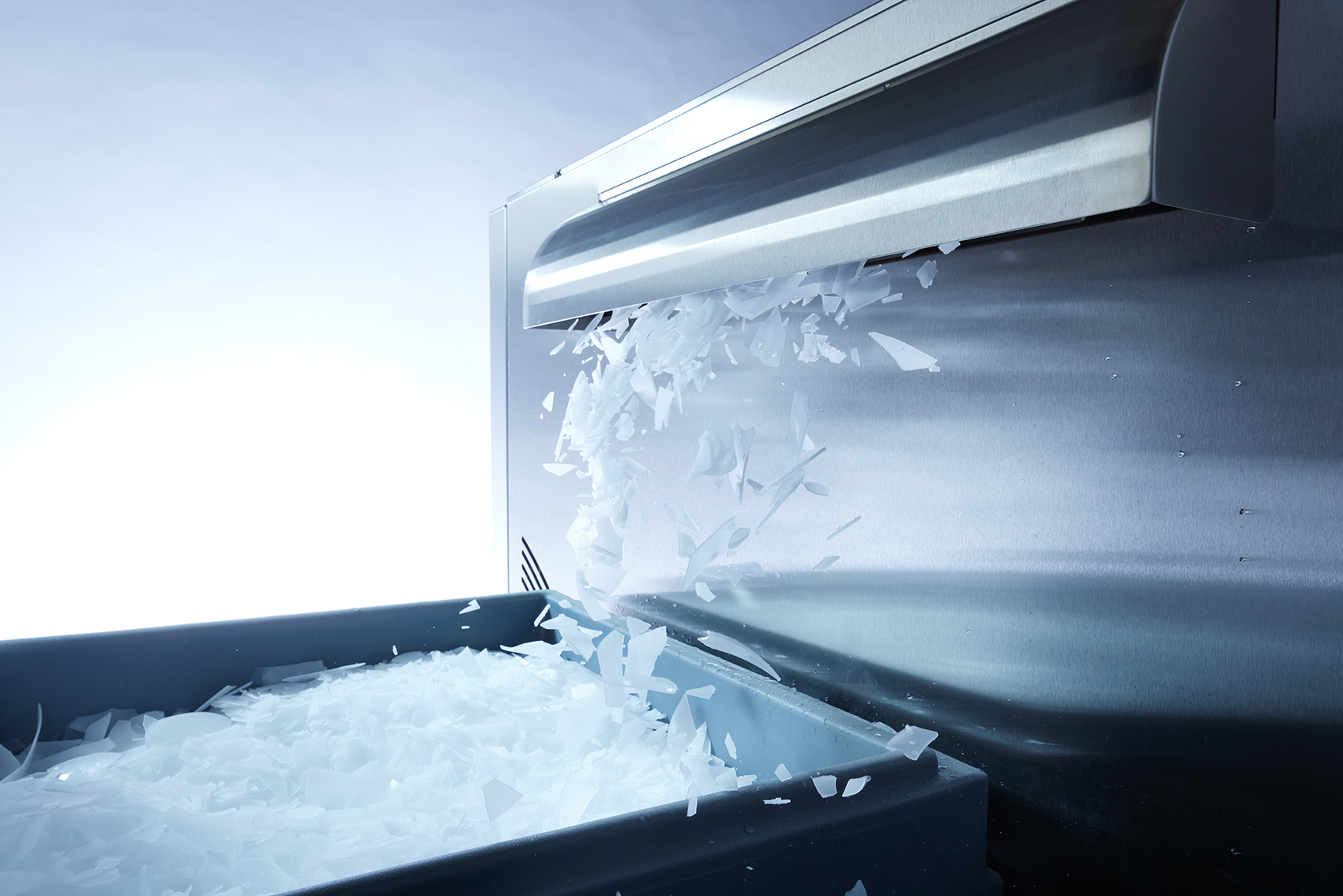

The compact flake ice machines MAJA-SAH-L offer a wide choice of ice producing units ranging from 250 kg ice output up to 3,000kg every 24 hours. With an integrated condensing unit, the MAJA-SAH perfectly meets any flake ice requirements of butcheries, bakeries, supermarkets, hotels, restaurants, catering businesses and various non-food applications.

Hygienic, food-safe ice production

MAJA flake ice machines are labeled HY-GEN protected. This stands for excellent sanitary conditions:

- Easy access to cleaning relevant parts from all sides without the use of tools

- Easily removable, round plastic water tank

- Water tank without built-in parts, angles, edges and screws allowing easy and thorough cleaning

- Automatic water pipe rinsing after 24 hours without ice production

- Special hygiene features in accordance with the German drinking water regulations

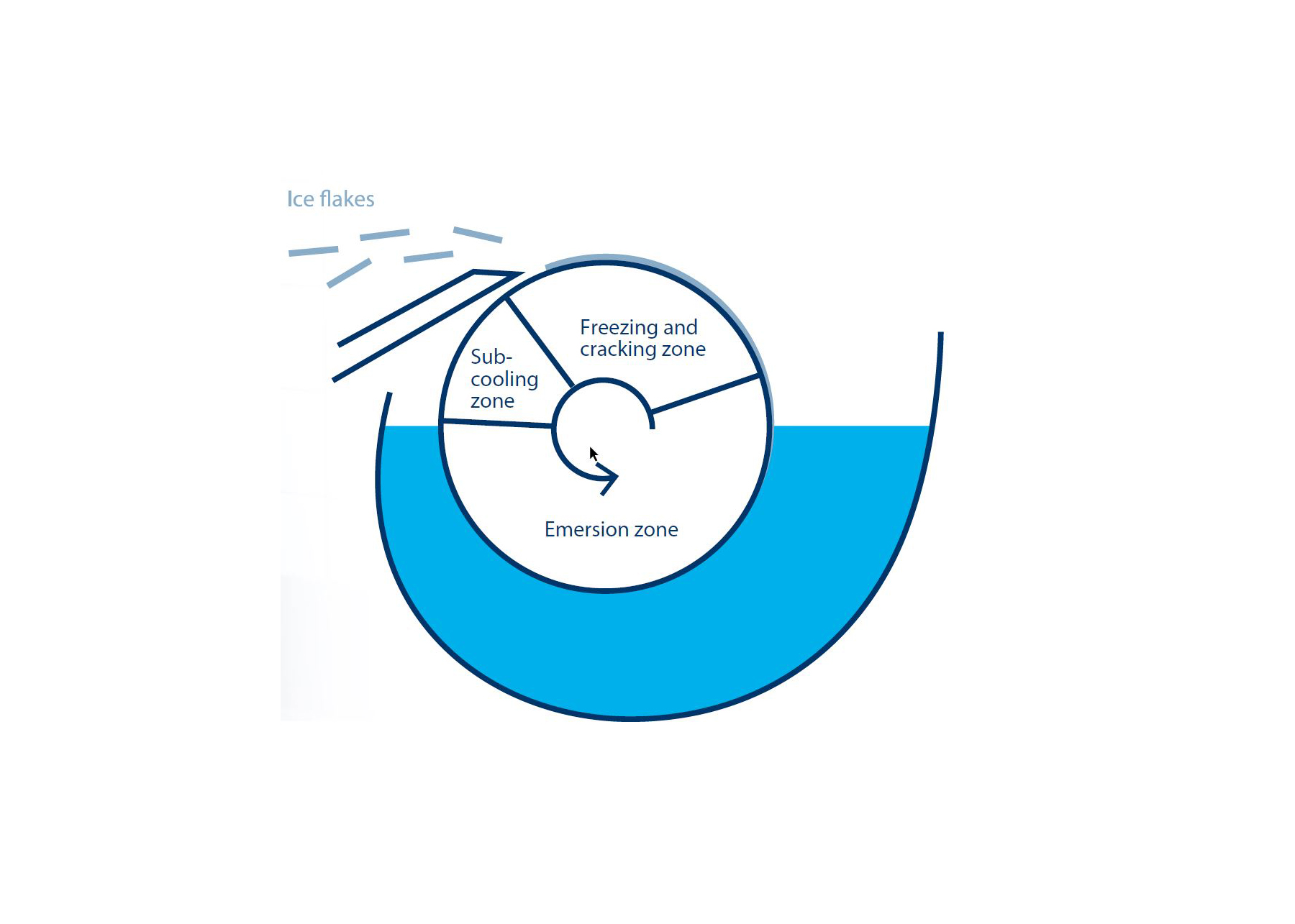

Refrigeration

- Integrated condensing unit in air-cooled execution (L), water-cooled execution (W) on demand

- Refrigerant R449A (GWP 1397)

- Integrated heat exchanger for optimum energy efficiency

- Refrigerant stop valve and refrigerant pump-down when the machine stops

Easy operation

- Easy operation by ON/OFF pushbuttons (MAJA SAH 250/500), or ON/OFF remote-control panel (MAJA SAH 800-3000)

- Control panels with program function optionally available

- Reliable SPS control unit

- Solid machine structure, frame and housing in stainless steel